In the precision world of food packaging, pharmaceutical protection, and electronic components, a material less than one-tenth the thickness of a human hair is quietly playing a critical role—double zero aluminum foil. The global double zero aluminum foil market reached tens of billions of RMB in 2024 and continues to expand at a significant compound annual growth rate, projected to reach new peaks by 2030.

What is double zero aluminum foil?

Aluminum foil can be categorized by thickness into three main categories: thick foil, single-zero foil, and double zero foil.

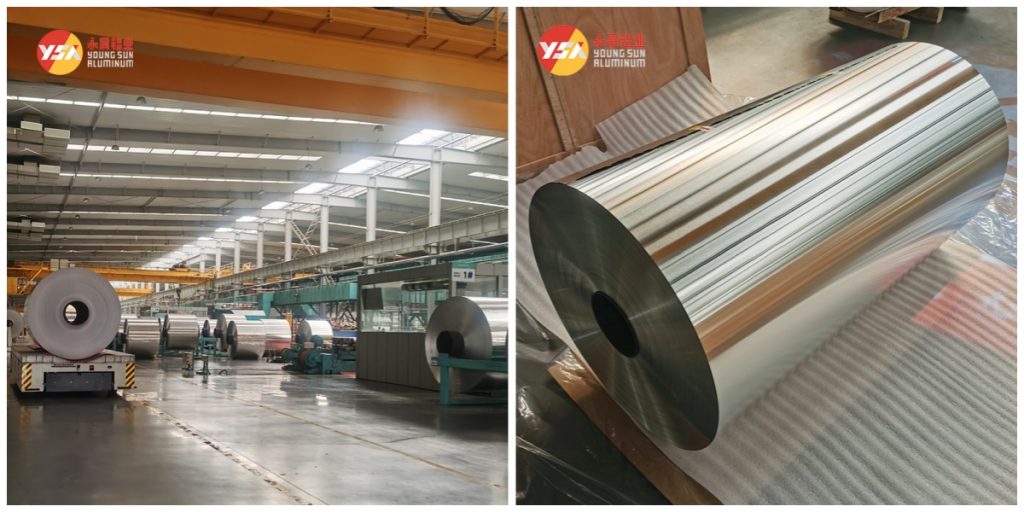

Double zero aluminum foil is a cutting-edge product of aluminum rolling technology. Its name stems directly from its thickness specification: when measured in millimeters, its thickness has two zeros after the decimal point (e.g., 0.006mm, 0.007mm). Yongsheng Aluminum has achieved world-leading mass production of 0.006mm thickness, equivalent to one-tenth the diameter of a human hair. The production of this type of aluminum foil represents the pinnacle of precision in metalworking, requiring a transformation through as many as 18 steps—from an initial 6.8mm aluminum billet, through complex processes such as cold rolling, high-temperature foil pressing, and lamination, to the ultra-thin material that can be shipped as a roll.

There are two production routes for double zero aluminum foil

- Traditional hot rolling: This involves melting, hot rolling, slab formation, cold rolling, and foil rolling. This process is complex and energy-intensive.

- Innovative casting and rolling: Yongsheng Aluminum’s independently developed, shortened casting and rolling process reduces electricity consumption by 800 kWh per ton of product, resulting in an annual energy saving of 300 million kWh and a reduction in carbon emissions by over 50%.

Table 1: Double zero aluminum foil thickness range and typical applications.

| Category | Thickness Range (mm) | Typical Products | Technical Difficulties |

| Double zero foil | <0.01 | Aseptic food packaging, high-end capacitor foil | pinhole control (<200 holes/m²), high-speed rolling stability |

| Single-zero foil | 0.01-0.1 | Pharmaceutical blisters, electronic shielding foil | balanced strength and ductility |

| Thick foil | 0.1-0.2 | Container foil, architectural decorative panels | Surface Flatness Control |

Applications of Double Zero Aluminum Foil in Various Fields

The breadth of applications for double zero aluminum foil is astonishing, permeating nearly every corner of modern life.

Food Packaging

It accounts for nearly 50% of global demand and is the core layer of freshness preservation systems for milk cartons, coffee packaging, chocolate coatings, and more. For example, the inner layer of aseptic milk cartons, covered with double zero aluminum foil, can extend shelf life by more than ten times while eliminating the need for preservatives, achieving the health benefits of “reducing salt and sugar without sacrificing freshness.”

Pharmaceutical Protection

With its 100% light-blocking properties and superior microbial barrier properties, it has become the preferred material for tablet blisters and vaccine packaging, with global annual demand experiencing steady growth.

Electronics and Energy

- Electromagnetic Shielding: A full aluminum wrapping completely isolates mobile phone signals.

- New Energy Battery Current Collector: Serves as a current collector in the positive electrode of lithium batteries and the positive and negative electrodes of sodium batteries. Sodium batteries, in particular, require aluminum foil for both the positive and negative electrodes, resulting in a demand of 700-1000 tons/GWh, more than double that of lithium batteries.

Table 2: Major Applications and Market Share of Double Zero Aluminum Foil

| Application Area | Global Market Share (%) | Core Function | Growth Driver |

| Food Packaging | 48.8% | Antibacterial, moisture-proof, and antioxidant | Rising demand for healthy foods |

| Pharmaceutical Packaging | 20.5% | Light-proof, sterile, and anti-counterfeiting | Improving global medical standards |

| Electronics | 18.7% | Electromagnetic shielding, capacitor dielectrics | Popularization of 5G and the Internet of Things |

| New Energy Batteries | 5.6% | Current collectors and electrode carriers | Accelerating commercialization of sodium batteries |

| Other | 6.4% | Decorative and industrial composite materials | Innovative material development |

Six Core Advantages of Double Zero Aluminum Foil

The wide applicability of Double Zero aluminum foil stems from its unique physical and chemical properties.

Ultimate Barrier Performance

It completely isolates oxygen, moisture, and microorganisms, extending the shelf life of food several times. Experiments have shown that milk packaged in Double Zero aluminum foil retains a flavor close to refrigerated milk at room temperature.

Safety and Environmental Protection

Aluminum foil is inherently non-toxic and odorless, meeting FDA food contact standards. Crucially, it is 100% recyclable and reusable, with recycled aluminum production consuming only 5% of the energy of virgin aluminum, significantly reducing its carbon footprint.

Lightweight and Economical

Unlimited thickness results in significant material savings. For example, Shengtong Technology’s 0.006mm product reduces weight by 33% per 10,000 square meters compared to traditional 0.009mm aluminum foil, directly reducing logistics costs.

Thermal Stability

It maintains no deformation or releases harmful substances during high-temperature sterilization, making it suitable for sterilization of various foods and pharmaceuticals.

Electromagnetic Shielding Effectiveness

- Its complete electromagnetic shielding makes it an ideal material for protecting precision electronic components and an essential component in 5G communications equipment and aerospace. Process Compatibility

- The surface can be laminated with plastic film and paper layers to form a multilayer material (such as a Tetra Pak), combining metal barrier properties with paper printability.

Double Zero Foil vs. Ordinary Aluminum Foil

Although both belong to the aluminum foil family, double zero foil differs fundamentally from traditional products.

Thickness and Performance

Ordinary single zero foil (0.01-0.1mm) is prone to breakage when folded due to thickness limitations, resulting in a high pinhole count of >500 holes/m². However, double zero foil maintains mechanical properties while keeping pinholes below 200 holes/m², achieving a true “sterile barrier.”

Production Thresholds

The rolling of double zero foil requires overcoming key technical bottlenecks such as rolling warpage and strip breakage control. Yongsheng Aluminum underwent 2,189 experiments to resolve the “age spot” oxidation problem on the aluminum foil surface. The root cause was micro-damage to the oxide layer caused by rolling vibration.

Cost and Value

Although double zero foil has a higher unit price, with processing fees of approximately 15,000-40,000 yuan/ton, the reduced unit area usage brings overall cost advantages. Battery-grade double zero foil has higher technical barriers, and processing fees can be more than double that of ordinary packaging foil.

Frontier Application Expansion

Ordinary aluminum foil cannot meet the ultra-thin current collector requirements of new energy batteries. Double zero foil (12-15μm) for power batteries has become a key material for improving battery energy density, with global annual demand growth exceeding 40%, far exceeding the 3-5% growth rate of traditional aluminum foil.

Summary

With the global “dual carbon” goals advancing, the double zero aluminum foil industry is ushering in a green revolution:

- Yongsheng’s short-process casting and rolling technology has achieved an annual reduction of over 240,000 tons of CO2 emissions, setting a new industry benchmark.

- The widespread use of intelligent production lines has enabled thickness control accuracy of ±0.1μm, and the booming sodium battery industry will further drive demand—global demand for battery aluminum foil is expected to reach 740,000 tons in 2025, creating a market space of nearly 30 billion yuan.

From ensuring food safety to enabling the new energy revolution, double zero aluminum foil, with a thickness less than a micron, carries the cornerstone functions of the modern industrial system. In the future, as more companies break through technological barriers and optimize environmentally friendly processes, this “invisible guardian” will continue to expand the boundaries of technology and life, and play a core role in the blueprint of sustainable packaging and clean energy.