Drug packaging plays a crucial role in the pharmaceutical industry, ensuring the safety, efficacy, and quality of medications. Various drug packaging materials are used, each with its unique properties and benefits. One such material is medicinal aluminum foil, which offers several advantages in drug packaging. This article will delve into the role of medicinal aluminum foil, exploring its characteristics, benefits, applications, and its significance in ensuring the integrity of pharmaceutical products.

Understanding Drug Packaging

Before diving into the role of medicinal aluminum foil, it is essential to understand the significance of drug packaging. Drug packaging serves multiple purposes, including protecting medications from external factors, such as light, moisture, oxygen, and contamination. It also aids in maintaining the potency and stability of drugs throughout their shelf life. In the pharmaceutical industry, drug packaging materials are carefully selected based on various factors like drug compatibility, regulatory requirements, patient safety, and convenience.

Common drug packaging materials used in the pharmaceutical industry include plastic, glass, aluminum foil, blister packs, and specialized materials designed for specific purposes.

Medicinal Aluminum Foil: An Overview

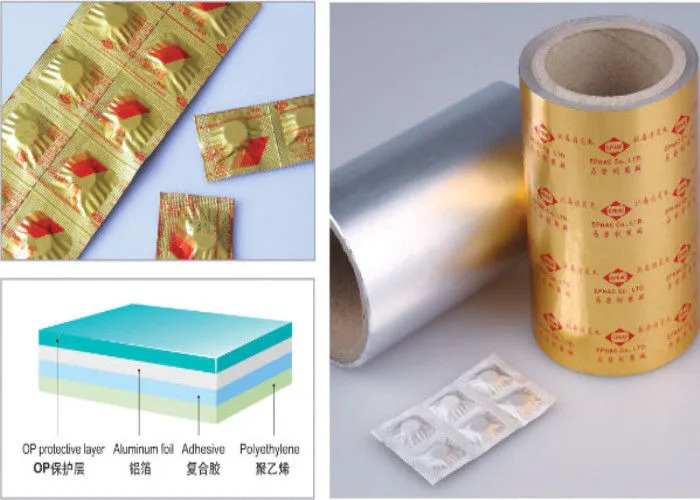

Medicinal aluminum foil is a specialized drug packaging material extensively used in the pharmaceutical industry. It is made from thin sheets of aluminum and exhibits unique characteristics that make it suitable for drug packaging. The foil is commonly laminated with other materials to enhance its barrier properties and protect the enclosed medications.

One of the key advantages of medicinal aluminum foil is its excellent barrier properties. It acts as a barrier against oxygen, moisture, and other environmental factors, thereby preserving the drug’s potency and stability. Aluminum foil also provides protection against light, which is particularly important for light-sensitive medications. Additionally, it offers moisture resistance, ensuring that the drugs remain unaffected by humidity. Moreover, aluminum foil exhibits temperature stability, safeguarding the medications from extreme temperatures during transportation and storage. It also possesses tamper-evident features, allowing for easy detection of any unauthorized access to the medication. The material of pharmaceutical aluminum foil is generally 8021, 8079, 8011, and the thickness is generally about 0.02mm.

Role of Medicinal Aluminum Foil in Drug Packaging

Medicinal aluminum foil plays a crucial role in drug packaging, primarily due to its protective properties and its ability to maintain the integrity of pharmaceutical products. Let’s explore its key roles:

Protection against environmental factors:

Medical aluminum foil uses as a barrier against oxygen and moisture, deterring their access into the container and offering protection from environmental elements. For medicines that are susceptible to oxidation or destruction in moisture conditions, this barrier protection is necessary. Aluminum foil serves as a protection, preserving the drug’s influence, effectiveness, and shelf life. What’s more, it guards against pollution, making sure that the drugs are still beneficial and safe to consume.

Light protection and preservation of drug efficacy:

Aluminum foil effectively blocks light, which is essential for medications that are susceptible to degradation when exposed to light. By shielding the drugs from light, aluminum foil helps maintain their efficacy throughout their shelf life.

Durability and safety during transportation and storage:

Aluminum foil is a durable material that provides excellent protection during transportation and storage. It can withstand external pressures, impacts, and temperature variations, ensuring that the medications remain intact and undamaged.

Tamper-evident features and ensuring product integrity:

Medicinal aluminum foil often includes tamper-evident features such as seals or indicators that show if the packaging has been tampered with. These features provide assurance to consumers and healthcare professionals about the integrity and safety of the medication.

Compatibility with different drug forms and dosage forms:

Aluminum foil is highly versatile and compatible with various drug forms and dosage forms, including tablets, capsules, powders, and liquids. Its flexibility allows for efficient packaging of different medications according to their specific requirements.

Applications of Medicinal Aluminum Foil in Drug Packaging

Medicinal aluminum foil finds wide application in various drug packaging formats. Some of the prominent applications include:

Blister packs:

Blister packs are widely used in the pharmaceutical industry, particularly for solid oral dosage forms. They consist of individual compartments or pockets that hold the medication, with aluminum foil forming the top layer. Aluminum foil in blister packs offers excellent protection against moisture, oxygen, and light, ensuring the stability and integrity of the enclosed drugs. Furthermore, blister packs promote patient compliance by providing an organized and convenient way to store and consume medications.

Strip packs and sachets:

Strip packs and sachets are commonly used for unit-dose packaging of solid oral medications. Aluminum foil is employed to create individual pockets or sachets that contain a single dose of the drug. This packaging format offers enhanced stability and protection for individual doses, preventing contamination and maintaining drug potency.

Parenteral packaging:

Parenteral drug packaging refers to the packaging of injectable medications such as ampoules, vials, and pre-filled syringes. Aluminum foil is extensively used in parenteral drug packaging to provide a sterile barrier and protect the medications from light, moisture, and microbial contamination. It ensures the safety and efficacy of injectable drugs, which are often highly sensitive to environmental factors.

Innovations and Advancements in Medicinal Aluminum Foil Packaging

In recent years, there have been several innovations and advancements in medicinal aluminum foil packaging to cater to evolving industry needs. Some notable developments include:

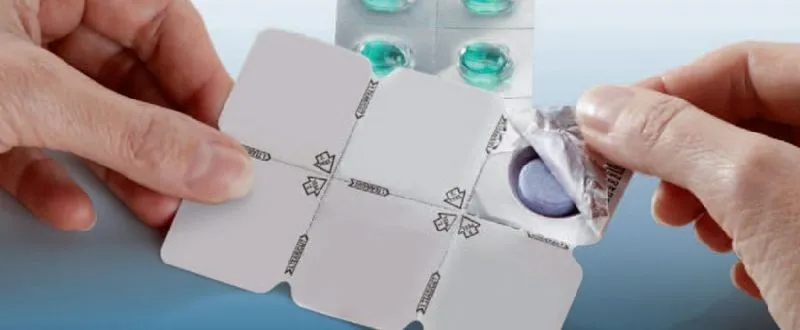

Child-resistant and senior-friendly packaging:

Packaging manufacturers have incorporated child-resistant and senior-friendly features into medicinal aluminum foil packaging. These features aim to prevent accidental ingestion by children and make it easier for elderly individuals to open the packaging safely.

Easy-to-open features for patient convenience:

Packaging designs now focus on providing easy-to-open features, ensuring patient convenience and improving medication adherence. This is particularly beneficial for patients with limited dexterity or those who may struggle with traditional packaging formats.

Sustainability and recyclability initiatives:

With increasing environmental concerns, the pharmaceutical industry has been actively adopting sustainable packaging practices. Medicinal aluminum foil, being a recyclable material, aligns with these initiatives. Manufacturers are incorporating recycled aluminum content into their foil production processes and promoting the recycling of used aluminum foil to reduce environmental impact.

Incorporation of smart packaging technologies:

Smart packaging technologies, such as RFID tags and temperature sensors, are being integrated into medicinal aluminum foil packaging. These technologies enable real-time monitoring of temperature, humidity, and other environmental factors, ensuring the integrity and quality of medications throughout the supply chain.

Quality Control and Safety Considerations

The manufacturing of medicinal aluminum foil follows stringent quality control measures to ensure its safety and reliability. Manufacturers adhere to regulatory requirements and guidelines, such as Good Manufacturing Practices (GMP), to maintain consistency in production processes. Quality control procedures include rigorous testing for barrier properties, heat-sealing strength, and overall integrity of the foil. Additionally, safety considerations are taken into account during the production and handling of aluminum foil to minimize the risk of contamination or product defects.

It is worth noting that concerns have been raised regarding the potential health risks associated with aluminum exposure. However, the amount of aluminum transferred from medicinal aluminum foil to the medication is typically negligible and well below the acceptable limits defined by regulatory bodies. Extensive research and studies continue to assess the impact of aluminum on drug stability and safety.

Environmental Impact and Recycling of Medicinal Aluminum Foil

Aluminum production, including the manufacturing of medicinal aluminum foil, does have an environmental impact. The extraction and refining of aluminum require significant energy consumption and can result in greenhouse gas emissions. However, aluminum is a highly recyclable material, with a relatively low energy requirement for recycling compared to primary production.

Recycling initiatives for aluminum foil are gaining momentum in the pharmaceutical industry. Recycling not only conserves natural resources but also reduces landfill waste. Proper recycling practices involve collecting used aluminum foil, segregating it from other waste, and sending it to specialized recycling facilities. From there, the recycled aluminum can be used to produce new aluminum foil or other aluminum products.

Medicinal aluminum foil plays a vital role in drug packaging, ensuring the protection, integrity, and efficacy of medications. Its barrier properties, light protection, moisture resistance, and tamper-evident features make it an ideal choice for ensuring the stability and safety of pharmaceutical products. Aluminum foil finds applications in blister packs, strip packs, sachets, and parenteral packaging, catering to various drug forms and dosage forms.

With ongoing advancements in packaging technology, medicinal aluminum foil continues to evolve. Innovations such as child-resistant features, easy-to-open designs, sustainability initiatives, and smart packaging technologies further enhance its functionality and safety.

As the pharmaceutical industry strives to prioritize patient safety, drug efficacy, and environmental sustainability, the role of medicinal aluminum foil remains crucial. By choosing appropriate packaging materials and ensuring compliance with regulatory standards, healthcare professionals and manufacturers can ensure the quality and integrity of medications throughout their lifespan.