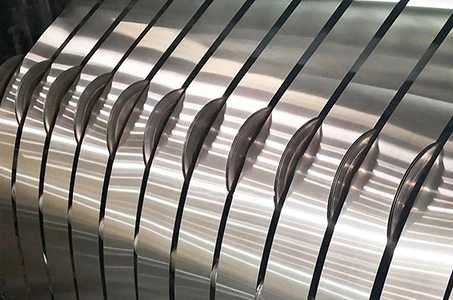

What Is Flat Aluminum Strips?

Flat aluminum strips refer to extruded solid aluminum strips that are very easy to use in different applications. These aluminum flat strips are mainly used in different manufacturing projects that require high corrosion resistance and lightweight materials. Aluminum flat strips have a rectangular and flat surface , ideally suited for use in the structural and construction fields. They are considered versatile tools that can drill, weld, reshape and cut into different shapes. Mainly used as support material for buildings and frames and are often found in hangers, vents, ladders, doors and heaters.

What Are The Applications Of Flat Aluminum Strips?

- Construction industry:

a. Roof and exterior wall panels: As a lightweight, corrosion-resistant solution, aluminum flat strips are widely used in the construction industry for the production of roofs and exterior wall panels (commonly used 3003 aluminum strips, 5052 aluminum strips). They offer aesthetic appearance and design flexibility.

b. Window frames and doors: 3003 flat aluminum strips are often used to make window frames and doors and are favored for their excellent structural strength and durability. They also have good thermal insulation properties, helping to achieve energy savings.

- Automobile industry:

a. Trim strips and decorative elements: Flat aluminum strips are widely used in the interior and exterior decoration of cars to add appeal to the car by improving the aesthetics of the interior and exterior. Aluminum flat strips are lighter in weight than traditional materials.

b. Heat shields and reflectors: Flat aluminum strips are used as heat shields and reflectors in automotive engine components to effectively manage heat and ensure the safety and efficiency of automotive systems.

- Electrical and electronics industry:

a. Wires and connectors: Flat aluminum strips have good electrical conductivity and are widely used in wires and connectors in power transmission (1050 aluminum strips are commonly used) to ensure efficient transmission and reliable connection of the power system.

b. Radiator and LED lighting: Aluminum flat strips (commonly used 6063 aluminum alloy) are used as heat sinks in electronic equipment and can dissipate heat efficiently. In addition, flat aluminum strips also play a role in energy-saving LED lighting.

- Packaging industry:

a. Caps and bottle caps: Aluminum flat strips (such as 8011 aluminum strip, 1235 aluminum strip) are used as caps and bottle caps in various packaging applications to ensure safe sealing. At the same time, aluminum flat strips are customizable and can meet the needs of brand and product differentiation.

b. Seals and gaskets: Flat aluminum strips such as 3105 aluminum strips are used for seals and gaskets in containers and systems. They are leak-proof and can resist the effects of chemical and environmental factors.

Why Do We Need Flat Aluminum Strips?

It is well known that the majority of aluminum alloys are heat treatable, meaning that after undergoing specific heat treatments, the alloys can enhance their tensile strength. Since aluminum is also thought to be non-magnetic, it can be used in close proximity to sensitive electronics and radio transmissions inside of vehicles without causing interference. Aluminum components are stronger and lighter than most metals. Flat aluminum strips can therefore be utilized in applications that don’t call for heavy materials because they are strong and lightweight.

Advantages Of Flat Aluminum Strips

There are several benefits to using aluminum flat strips. Here are some of the most prominent advantages of flat aluminum strips.

1. Easy to process: Flat aluminum strips are very easy to process through welding, riveting and machining, making them suitable for the construction of various products such as connectors and hydraulic systems.

2. Electrical and thermal conductivity: Flat aluminum strips have excellent thermal and electrical conductivity and are very suitable for use as electronic radiators, etc.

3. Easy to form: Cold forming refers to the process of forging metal at room temperature, thereby improving the strength and yield of the metal. Aluminum strips are ideally suited to the cold forming process and can be used to create strong and reliable products such as couplings and bicycle frames.

4. Corrosion Resistant and Strong: Aluminum strips have high corrosion resistance and strength levels. This makes them ideal for different applications, especially in harsh environments.

How To Make A Flat Piece Of Aluminum Strip?

- Material preparation: Select suitable aluminum alloy coils as raw materials. Select the appropriate aluminum alloy grade and thickness as needed.

- Cutting: Use cutting equipment (such as shears machines) to cut the aluminum coils into long strips according to the required size. Make sure the cutting edges are flat and plumb.

- Straightening: The cut aluminum alloy coils may have some bending or warping. Use straightening equipment, such as a straightening machine, to straighten the aluminum strips so they become straight.

- Milling or grinding: Use tools such as a milling machine or grinding wheel to mill or grind the surface of the aluminum strip to obtain a smooth and flat surface.

- Cold rolling or hot rolling: The aluminum flat strip is rolled through a cold rolling mill or a hot rolling mill to gradually thin it and form the required width and thickness. Cold rolling is suitable for thinner aluminum strips, while hot rolling is suitable for thicker aluminum strips.

- Straightening again: The rolled aluminum strip may have some bending or warping. The aluminum flat strip is again straightened using straightening equipment to obtain a smooth, flat shape

- Surface treatment: As needed, the surface of the aluminum strip is further treated, such as anodizing, spraying, polishing, etc., to enhance its corrosion resistance or improve its appearance.

- Inspection and trimming: Conduct quality inspection on the manufactured flat aluminum coil strips to ensure that the size, surface quality and flatness meet the requirements. Repair or repair if necessary.

How Can We Help With Your Flat Aluminum Strips Project?

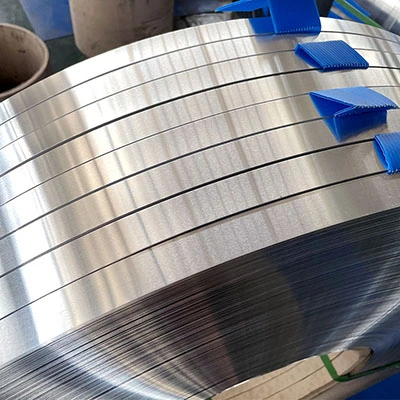

Yongsheng has established an experienced and skilled professional team to ensure the production of high-quality flat aluminum strips for your different projects. We can supply 1050, 1060, 1100, 3003, 5052, 5083, 6061, 8011 aluminum strips and other hot-selling products. We will provide you with free samples. Customers are welcome to come to inspect the factory and we look forward to establishing a long-term cooperative relationship with you!

Yongsheng Aluminum has a series of modern equipment to ensure the rapid and efficient production of flat aluminum strips. Our staff will take you through the entire production process from raw material production to after-sales.