3003 aluminum coil is a popular aluminum alloy coil. So far, China remains the world’s leading aluminum exporter. The United States, Japan, South Korea, and Australia are the most traditional trading partners among the major export destinations. Yongsheng aluminum coils are exported not only to the traditional trading partners listed above, but also to Singapore, Germany, Canada, the United Kingdom, Saudi Arabia, Ukraine, Spain, Poland, and other countries.

The industry anticipates that in 2023, spurred by the economic resiliency of the United States, India, ASEAN, and other countries and regions, the already tight supply imbalance in aluminum will widen further, driving up prices and making aluminum the best-performing asset class. Aluminum alloys that are commonly used around the world include 6063 aluminum alloy, 6061 aluminum alloy, 5052 aluminum alloy, and 3003 aluminum alloy. This essay will focus on the production, performance, benefits, and applications of 3003 aluminum coils in order to help you grasp them as soon as possible.

Line Of Production:

The production process of aluminum coils consists of several steps:

Melting: Primary aluminum is melted in a casting furnace, the molten aluminum is cast into ingots, and then rolled into sheets of the desired thickness.

Hot rolling: Homogeneous aluminum is hot rolled to reduce its thickness and increase its length. Hot rolling takes place at high temperatures, usually above the recrystallization temperature of aluminum, to obtain the desired mechanical properties and shape. The aluminum passes through a series of rolling mills, gradually reducing its thickness to the desired specification.

Cold Rolling: After hot rolling, aluminum coils can be cold rolled to further refine their thickness and surface finish. Cold rolling is carried out at room temperature and the aluminum coil passes through a series of rolling mills to reduce its thickness while improving its dimensional accuracy and surface quality.

Annealing: Cold rolled aluminum coils may undergo an annealing process to remove internal stresses and improve their formability. Annealing involves heating an aluminum coil to a specific temperature and then gradually cooling it. This process helps to soften the material and enhance its mechanical properties.

Finishing: After the annealing process, aluminum coils may undergo various finishing operations, such as trimming edges, cutting to size, surface cleaning or applying protective coatings. These steps are performed to meet specific customer requirements or downstream manufacturing processes.

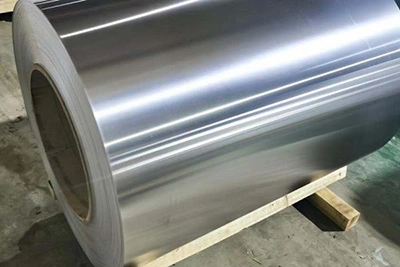

Coiling: The final step is to roll the aluminum strip into large coils for handling, transportation and storage. The coiled aluminum rolls are typically packaged and prepared for shipment to customers or further processing facilities.

Properties Of 3003 Aluminum Coil:

Mechanical characteristics: The tensile strength of 3003 aluminum coil ranges from 120 to 160 MPa, making it medium-strength and capable of withstanding high pressure without deforming. Additionally, 3003 aluminum coils may be easily bent, curved, and moulded without cracking or breaking thanks to their high elongation of roughly 25–35%.

Physical properties: The density of 3003 aluminum coil is low, about 2.73 g/cm3. Aluminum coils have a high thermal conductivity, typically around 167 W/m-K at room temperature, so it is also used in electronic applications such as radiators and heat exchangers. Its conductivity at room temperature is typically about 40% of the International Annealed Copper Standard (IACS). This means it can conduct electricity efficiently, making it suitable for use in electrical applications such as wires, conductors and electrical contacts.

Chemical properties: The main component of 3003 aluminum coil is aluminum, generally more than 98%, and also contains a small amount of additional elements. The main alloying element is manganese (Mn), which accounts for approximately 1-1.5% of the composition. Other trace elements include copper (Cu) and iron (Fe), both typically present in amounts below 0.7%. Offers excellent corrosion resistance and lightweight properties. The surface of 3003 aluminum coils can also be treated through various methods such as anodizing, painting or coating, which can enhance its appearance and provide corrosion protection.

Formability Of 3003 Aluminum Coil:

3003 aluminum coil is known for its excellent forming and bending properties. It belongs to the 3xxx series of aluminum alloys, is not heat treatable, and has a manganese content of about 1-1.5%. The bending ability of 3003 aluminum coil is described in detail below:

Due to its outstanding formability, 3003 aluminum coil is appropriate for a wide range of applications that call for bending and shaping. It is simple to shape into a wide range of shapes, including cylinders, cones, curves, and intricate patterns. Furthermore, the moderate strength of 3003 alloy enables it to bear the forces brought on by bending without splitting or fracturing. But be cautious that excessive bending or a radius that is too tiny can lead to surface deformation or cracking.

The minimum bend radius for 3003 aluminum coil depends on a number of factors including the thickness of the material, tempering conditions, and the type of bending process used. As a general guideline, the minimum recommended bend radius for 3003 aluminum is usually equal to or greater than the thickness of the material. For example, if you have a 0.040″ (1mm) thick 3003 coil, the minimum bend radius is usually about 0.040″ (1mm) or slightly larger. There are various bending methods for 3003 aluminum coil, including air bending, edge bending, embossing and rotary stretch bending. The choice of method depends on the specific application, part design and available equipment. Proper bending techniques and tools must be used to ensure precise bends and avoid damage to the material.

Advantages Of 3003 Aluminum Coil:

3003 aluminum coil is a versatile choice for a variety of applications, offering several benefits. First, 3003 aluminum is a non-heat-treatable alloy with excellent corrosion resistance, making it suitable for a variety of applications in corrosive environments. It can also be easily shaped and bent without compromising its structural integrity. Additionally, 3003 aluminum has medium strength and high weldability, allowing for an efficient manufacturing process. The alloy also has high thermal conductivity, making it ideal for heat dissipation applications. Compared with other alloys, 3003 aluminum coil has an economical cost, making it an ideal choice for many industries.

Applications Of 3003 Aluminum Coil:

Heat exchanger:

The heat transfer characteristics of 3003 aluminum coil make it suitable for the manufacture of heat exchangers. These coils allow for rapid and even heat dissipation, which promotes efficient heat exchange between fluids. Industries such as HVAC (heating, ventilation, and air conditioning) and refrigeration make extensive use of these coils for their heat transfer requirements.

Packaging:

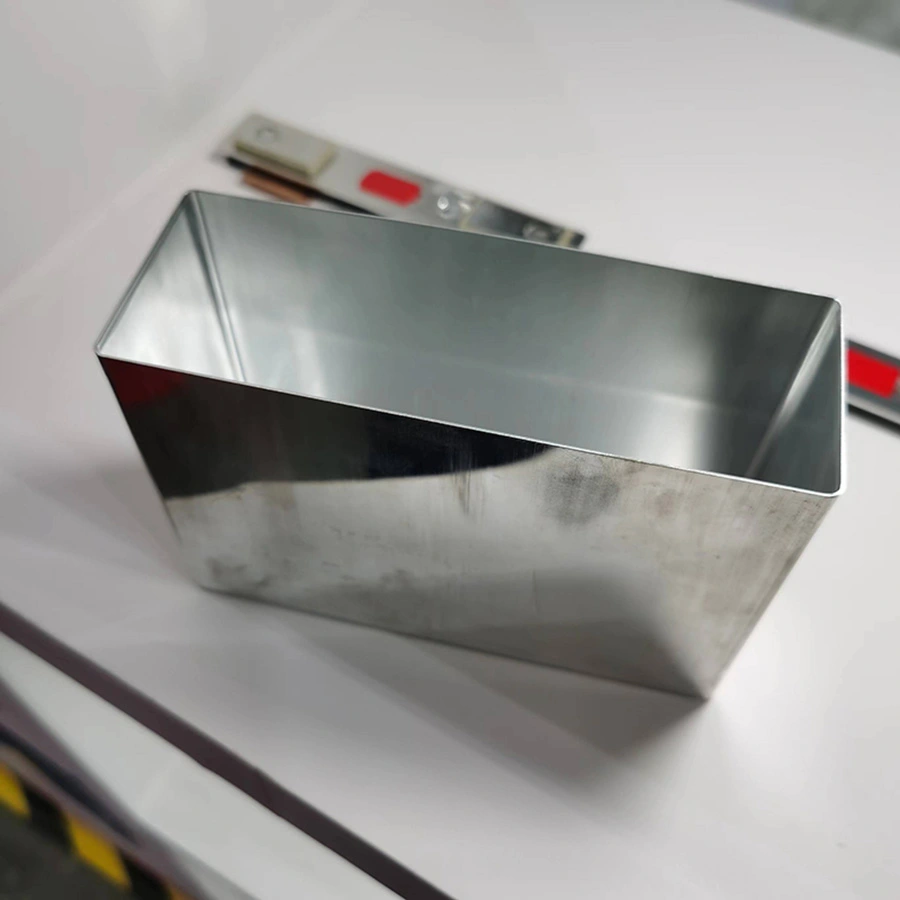

3003 aluminum coils are widely used in the packaging industry. Their malleability allows them to be easily formed into different shapes and sizes, making them suitable for making containers, cans and lids. In addition, the rolls have excellent barrier properties, protecting the contents from moisture, light and other external factors that can affect product quality and shelf life.

Electrical conductor:

Aluminum coil in 3003 has strong electrical conductivity, making it ideal for use in power battery casings and electrical conductors. Power lines, bus bars, and other electrical components that require effective electricity conductivity employ these coils. Energy loss during transmission is minimized by 3003 aluminum’s strong electrical conductivity.

Comparison With Other Aluminum Alloys:

3003 aluminum coil and 3004 aluminum coil both belong to the 3000 series aluminum alloy. The chemical composition of the two is very similar. 3004 shows higher strength and corrosion resistance than 3003. However, the processing performance of 3003 aluminum is better than that of 3004 aluminum alloy, the price is also more affordable than 3004, and it is more suitable for cold working processes.

3003 aluminum coil has high corrosion resistance in normal atmosphere and humidity environment. Compared with 3105 aluminum coils, 3003 aluminum coils are more affordable and suitable for some cost-sensitive applications. Aluminum coil 3003 is widely used in the construction and decoration fields. Its good corrosion resistance and formability make it the first choice for roofing, siding and other materials.