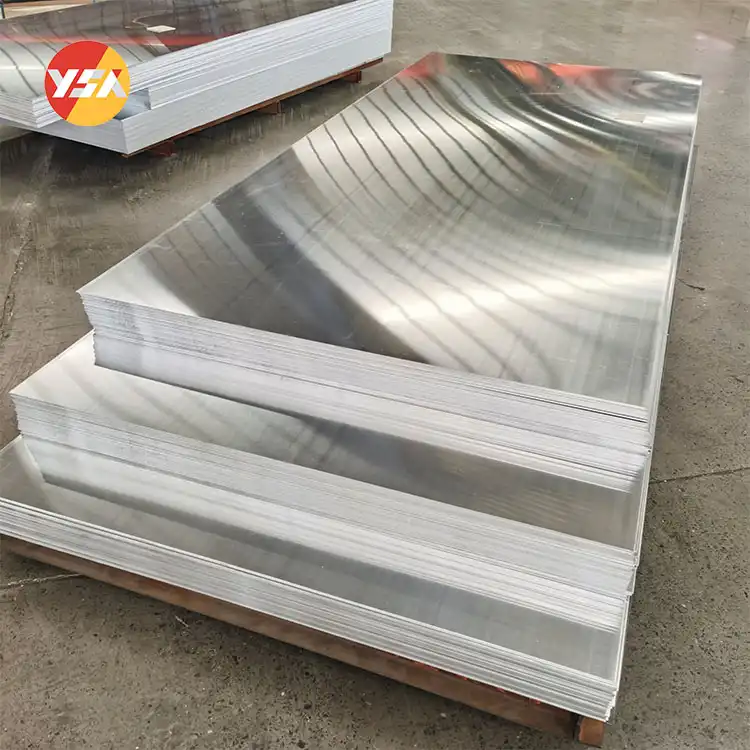

What is Cold Rolling Aluminum Sheet Plate?

Cold rolling aluminum sheet plate refers to a manufacturing process used to produce aluminum sheets or plates with improved mechanical properties and surface finish. Cold rolling aluminum sheet plate involves passing the aluminum through a series of rollers at room temperature to reduce its thickness and shape it into the desired dimensions. The process of cold rolling aluminum sheet plate is called “cold rolling” because cold rolling aluminum sheet plate is performed without heating the aluminum, in contrast to hot rolling, which involves working the metal at elevated temperatures.

Aluminum Sheet Cold Rolling Production Process

The production process of cold rolling aluminum sheet plate involves several stages to transform raw aluminum into a finished product. Let’s delve into the key steps of the process for cold rolling aluminum sheet plate :

- Casting and Homogenization: The process begins with the casting of molten aluminum into large ingots or billets. These solidify and are then subjected to a homogenization treatment to ensure a uniform composition and structure throughout the material.

- Preheating: The billets are preheated to a specific temperature to facilitate subsequent deformation during rolling. This heating process improves the material’s plasticity and reduces the risk of cracking or tearing during rolling.

- Hot Rolling: In this initial stage, the preheated aluminum billet is passed through a series of hot rolling mills. These rolling mills consist of multiple rollers that compress and elongate the billet, reducing its thickness and increasing its length. Hot rolling is performed at elevated temperatures to enhance plastic deformation and reduce the material’s strength.

- Annealing: After hot rolling, the aluminum sheet or plate undergoes an annealing process. Annealing involves heating the material to a specific temperature and then slowly cooling it. This step helps relieve internal stresses, refine the grain structure, and improve the aluminum’s mechanical properties.

- Cold Rolling: The annealed aluminum sheet or plate is now ready for cold rolling. In this stage, the material is passed through a series of cold rolling mills, which consist of pairs of rollers. The rollers exert pressure and compress the aluminum, reducing its thickness further. Cold rolling is performed at room temperature, imparting greater strength and improved surface finish to the aluminum.

- Intermediate Annealing: Depending on the desired final thickness and properties, intermediate annealing may be carried out between cold rolling passes. This intermediate annealing step helps restore the material’s ductility, relieve accumulated stresses, and ensure uniform thickness throughout the sheet or plate.

- Final Cold Rolling and Finishing: The cold rolling process is repeated several times until the desired final thickness is achieved. Each pass through the rolling mills reduces the thickness of the aluminum sheet or plate. The final cold-rolled product has improved mechanical properties, such as increased strength and hardness. After the final cold rolling pass, the aluminum sheet or plate may undergo surface treatments, such as leveling, cleaning, and edge trimming, to meet specific requirements.

- Final Annealing and Quality Control: To further enhance the material’s properties and ensure dimensional stability, a final annealing process may be performed. This annealing step also helps eliminate any residual stresses and refine the microstructure of the aluminum sheet or plate. Quality control measures, including inspections and tests, are conducted to verify that the cold-rolled aluminum meets the required specifications and standards.

- Packaging and Distribution: Once the cold rolling process is complete and quality checks are performed, the aluminum sheet or plate is packaged and prepared for distribution to customers. Proper packaging ensures protection during transportation and storage.

What Are The Requirements For Cold Rolling Aluminum Sheet Plate?

| Requirement | Description |

| Raw Material | High-quality aluminum alloy sheets with uniform chemical composition, proper thickness, and flatness for consistent cold rolling process. |

| Rolling Mill Equipment | Specialized rolling mills equipped with precise control systems, high rolling forces, and adjustable roll gaps to achieve the desired thickness reduction. |

| Lubrication | Adequate lubrication at the roll bite to minimize friction and prevent surface defects and damage to the aluminum sheet during the rolling process. |

| Temperature Control | Accurate temperature control to maintain the desired rolling temperature range, typically at room temperature, to ensure consistent material properties. |

| Roll Surface Condition | Smooth and clean roll surfaces without defects or contaminants to avoid surface imperfections on the aluminum sheet during the rolling process. |

| Roll Alignment | Proper alignment of rolls to ensure uniform thickness reduction and prevent edge cracking or uneven deformation of the aluminum sheet. |

| Tension Control | Precise tension control throughout the rolling process to prevent material slippage, wrinkles, or excessive strain on the aluminum sheet. |

| Annealing | Post-rolling annealing process to relieve residual stresses, improve material properties, and enhance flatness and dimensional stability of the sheet. |

| Quality Inspection and Testing | Comprehensive inspection and testing of the cold-rolled aluminum sheets for dimensional accuracy, surface quality, mechanical properties, and defects. |

| Packaging | Proper packaging to protect the cold-rolled aluminum sheets from damage during transportation and storage, preserving their quality and surface finish. |

Hot Rolling Aluminum Sheet Plate vs Cold Rolling Aluminum Sheet Plate

| Characteristic | Hot Rolling Aluminum Sheet | Cold Rolling Aluminum Sheet |

| Process | Aluminum is heated to high temperatures and rolled at elevated temperatures | Aluminum is rolled at ambient temperature |

| Temperature | High temperatures (above recrystallization temperature) | Room temperature |

| Thickness Reduction | Large thickness reduction in a single pass (30%–90%) | Incremental thickness reduction in multiple passes (5% – 30% per pass) |

| Mechanical Properties | Coarse-grained structure, reduced strength, improved ductility | Improved strength, hardness, and dimensional accuracy |

| Surface Finish | Rougher surface finish | Smoother and more uniform surface finish |

| Cost | Higher energy consumption and capital investment | Lower energy consumption and equipment requirements |

| Applications | Structural components, automotive panels, general fabrication | Electronics, appliances, aerospace, automotive body panels |

Aluminum Sheet Manufacturers Near Me

China’s top manufacturer and supplier of aluminum is Henan Yongsheng Aluminum Co., Ltd. We prioritize our consumers while maintaining tight quality control. We look forward to working closely with you and offering you services for high-quality aluminum material goods. Please get in touch with us if you would like the most recent and competitive rates per kg (kilogram) or per ton of standard weight.