One popular material used in RV construction is RV aluminum. In this article, we will explore the use of RV aluminum, including the specific parts that utilize aluminum and the series of aluminum alloys commonly employed. Additionally, we will delve into the advantages of aluminum RVs and address the frequently asked question of whether RV aluminum or fiberglass are better suited for different needs.

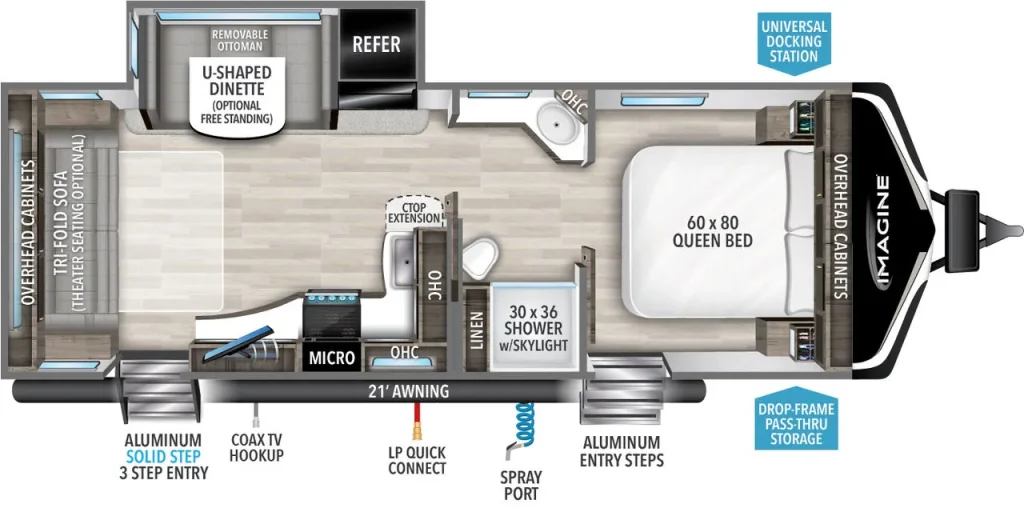

RV aluminum:Which parts of the RV use aluminum?

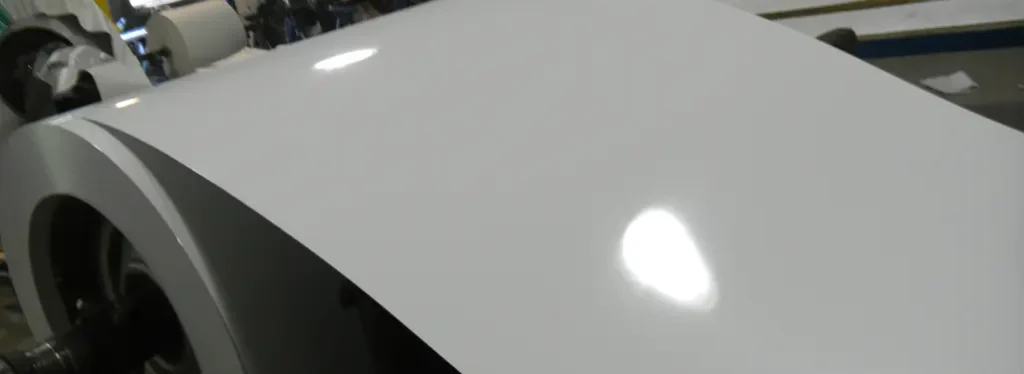

1.External Body: RV exterior body panels are frequently made of RV aluminum. It offers resilience to rust and corrosion, strength, and durability. Because aluminum panels are lightweight, they can tow better and use less fuel.

2. Framework and Structure: RVs’ framework and structure are made of RV aluminum. It maintains the vehicle’s structural integrity while minimizing its weight. Better handling and maneuverability are made possible on the road as a result.

3. Roofing: Aluminum roofs are a common sight on RVs. RV aluminum is a strong, lightweight material that is resistant to many types of weather. It aids in preventing possible damage and water leaks from entering the RV’s interior.

4. Interior Components: A variety of RV interior components are also made of RV aluminum. Cabinets, countertops, fixtures, and other fittings contain it. For these applications, aluminum is the material of choice because it is lightweight, moisture-resistant, and low maintenance.

5. Heat Dissipation: RV aluminum is a highly effective heat conductor. It ensures effective cooling in RVs by dissipating heat produced by the engine or other systems through heat sinks and radiator components.

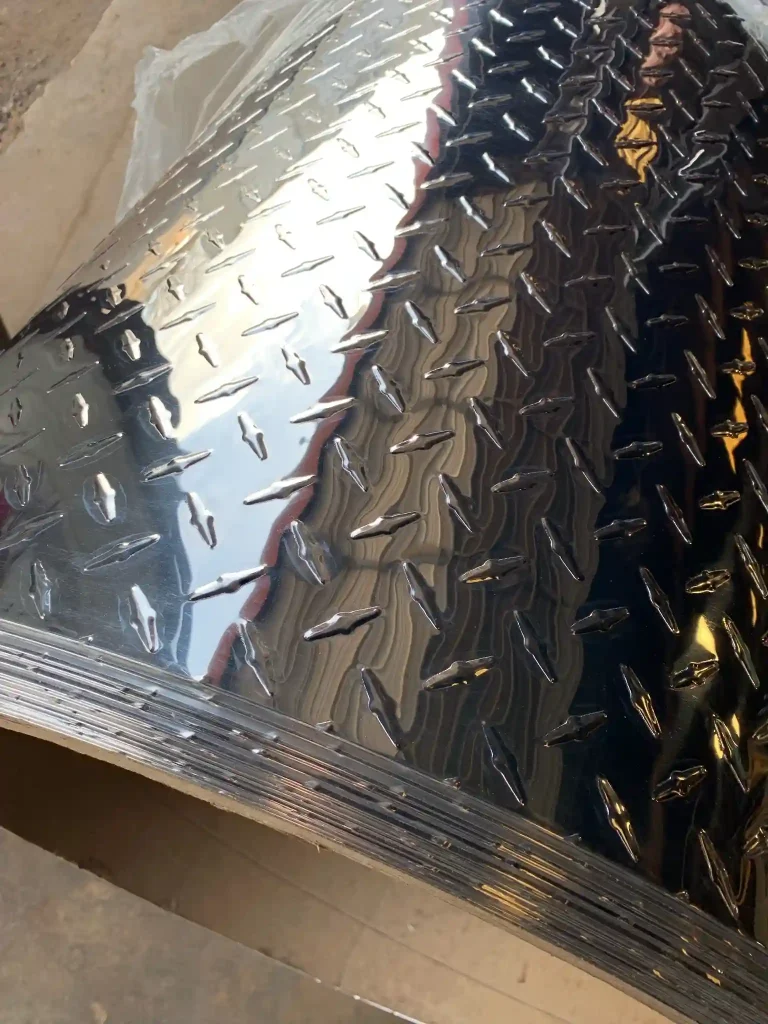

6. Awnings and Accessories: RV aluminum is a common material for awnings for RVs, outdoor storage areas, and other accessories. Because of its lightweight design and resistance to corrosion, it can be used outside.

Aluminum has many benefits when building an RV, including being lightweight, strong, resistant to corrosion, and having good heat management. However, it’s vital to remember that aluminum can be more expensive than other materials, and that repairs or modifications might require specific tools and knowledge. When all is said and done, aluminum significantly enhances the longevity, functionality, and aesthetics of RVs.

Which aluminum series are used in RVs?

Various series or alloys of aluminum can be utilized in the construction of RVs, contingent upon the manufacturer’s preferences and particular needs. The following aluminum alloys are frequently utilized in RV construction:

1. 5000 Series: RV siding and exterior panels frequently use aluminum alloys from the 5000 series, such as 5052 and 5083 aluminum. These alloys are appropriate for outdoor applications because of their outstanding formability, high strength, and good resistance to corrosion.

2. 6000 Series: RV frames, structural elements, and interior components are frequently made of aluminum alloys from the 6000 series, especially 6061 and 6063 aluminum. These alloys offer a harmonious combination of formability, weldability, and strength. They are frequently selected due to their affordability and adaptability.

3. 3000 Series: Several interior components of recreational vehicles (RVs) are made of aluminum alloys from the 3000 series, including 3003. These alloys have outstanding corrosion resistance, moderate strength, and good formability. Cabinets, countertops, and other fixtures frequently use them.

4. 7000 Series: RV specialized applications use high-strength aluminum alloys, such as 7075, from the 7000 series. Although they are less common in general RV construction, they may be used for certain structural elements that must have extraordinary strength, like heavy-duty chassis or parts that bear weight.

It is significant to remember that different RV manufacturers may use different aluminum alloys for different parts of the RV depending on the requirements and unique qualities of each alloy. In order to satisfy their unique requirements, manufacturers may also use proprietary blends or specially made alloys.

Advantages of aluminum RVs

1. Lightweight: RV aluminum is significantly lighter than traditional materials like steel. This weight advantage allows RV manufacturers to reduce the overall weight of the vehicle, resulting in improved fuel efficiency, easier towing, and increased cargo-carrying capacity.

2. Corrosion Resistance: Aluminum has a high degree of corrosion resistance, especially in humid and abrasive environments. Given that RVs frequently encounter rain, humidity, and road salt, this is an important consideration. Over time, aluminum’s resistance to corrosion aids in preserving the vehicle’s structural integrity and appearance.

3. Durability: Despite the rigors of road travel, aluminum is a material that is resilient. Compared to certain other materials, it is less prone to denting or deformation because of its strong impact resistance. Because of its durability, the RV is guaranteed to withstand unexpected impacts, temperature swings, and rough terrain.

4. Easy Maintenance: Aluminum surfaces are relatively easy to clean and maintain. They can be washed with mild soap and water to remove dirt and grime. Additionally, aluminum does not require painting or coating to maintain its corrosion resistance, further simplifying maintenance requirements.

5. Design Flexibility: Aluminum is highly malleable and can be easily formed into complex shapes. This allows RV manufacturers to create sleek and aerodynamic designs, maximizing interior space and optimizing fuel efficiency.

6. Recyclability: Aluminum’s high degree of recyclable nature adds to its environmental friendliness and sustainability. RV manufacturers can lessen the vehicle’s carbon footprint and encourage an environmentally friendly mindset by using aluminum in the construction process.

RV aluminum is used in the body panels, roofs, frames, doors, and interior fixtures, among other parts of the vehicle. It is a preferred option in the RV industry because it provides a balance of strength, weight savings, corrosion resistance, and design flexibility.

FAQ: Which is better? Fiberglass or aluminum RV?

The choice between fiberglass and aluminum for an RV depends on various factors, and both materials have their own advantages and considerations. Here’s a comparison of fiberglass and aluminum RVs:

Aluminum RVs:

1. Strength and Durability: Aluminum is a strong and durable material that can withstand rough road travel, impacts, and harsh weather conditions. It is less prone to cracking than fiberglass and can provide better protection in certain scenarios.

2. Repairability: Aluminum is generally easier to repair than fiberglass. Damaged aluminum panels can be welded or replaced more easily, while fiberglass repairs may require specialized knowledge and materials.

3. Customization: Aluminum RVs offer more customization options, as aluminum can be easily modified, cut, and welded. This can be beneficial for those who want to personalize their RV or make modifications down the line.

4. Cost: Aluminum RVs tend to be more cost-effective in terms of initial purchase price compared to fiberglass models, although this can vary depending on the specific manufacturer and features.

What’s more, aluminum RVs can offer advantages in specific weather conditions:

1. Cold Climates: Aluminum has better cold-weather performance compared to fiberglass. It is less prone to cracking or shattering in extremely low temperatures. Additionally, aluminum has higher thermal conductivity, which means it can transfer heat more efficiently. This can help prevent issues like ice damming on the roof, as the heat from the interior can dissipate through the aluminum panels, aiding in melting snow and ice.

2. Hailstorms: Aluminum RVs provide better resistance to hail damage compared to fiberglass. Aluminum panels are more resilient and less likely to dent or crack when subjected to hail impacts. This can be advantageous in regions prone to severe hailstorms, where the risk of damage to the RV exterior is higher.

3. Coastal Areas: Aluminum’s natural resistance to corrosion makes it a suitable choice for RVs in coastal areas. Saltwater and humidity in coastal environments can accelerate the corrosion process, but aluminum’s inherent corrosion resistance helps protect the RV from such damage.

4. High UV Exposure: Aluminum RVs can better withstand prolonged exposure to intense sunlight and UV radiation. Aluminum panels are less likely to fade or deteriorate under the sun’s UV rays, which can be a concern for fiberglass RVs over time. This can be advantageous in regions with high levels of sunlight and where extended outdoor use is expected. While aluminum RVs may have advantages in specific weather conditions, proper care and maintenance are still necessary to ensure their longevity and performance. Regular cleaning, inspection, and preventive measures should be taken to protect the RV from any environmental factors it may encounter.