Tobacco foil packaging is necessary in the tobacco industry. It serves as protection to keep the quality, flavor, and freshness of tobacco products. We will present a detailed introduction to it in this article, analyzing its traits, purposes, types, production method, safety considerations, advancements, and prospects for the future. Knowing the importance of tobacco foil will help us better understand how it protects the quality of tobacco products.

What’s Tobacco Foil

Tobacco foil is a specialized packaging material used in the tobacco industry. It is generally made from aluminum or a combination of aluminum and paper. The foil is designed to offer a barrier against moisture, air, and light, which can adversely influence the quality of tobacco. By creating a protective layer, it helps keep the freshness, flavor, and aroma of tobacco products, making sure a satisfying smoking experience for consumers.

Compared to other packaging materials, such as plastic or paper, tobacco foil provides unique advantages. It has excellent heat resistance and conductivity characteristics, making it to stand the high temperatures generated during smoking without compromising its integrity. What’s more, it is lightweight, flexible, and easy to handle, making it ideal for packaging many kinds of tobacco products. Generally speaking, the thickness of cigarette foil is 0.07mm aluminum foil.

Characteristics of Tobacco Foil

Tobacco foil possesses specific characteristics that make it suitable for tobacco packaging. These characteristics include:

- Thickness and weight: It is available in various thicknesses and weights, depending on the specific requirements of the tobacco product.

- Surface finish: The foil can have different surface finishes, such as plain or embossed, to enhance its appearance and tactile feel.

- Heat resistance and conductivity: Because foil can stand high temperatures without melting or deforming, it maintains its shape while being smoked. What’s more, due to its effective heat conductivity, the tobacco burns continuely and evenly.

The Function of Tobacco Foil in Tobacco Packaging

Tobacco foil serves several important functions in tobacco packaging:

- Protection against moisture and air: By serving as a barrier, foil keeps air and moisture out of the tobacco product. The moisture level of the tobacco is preserved, protecting it from drying out and losing taste and aroma. What’s more, the foil prevents moisture from the environment from entering into the tobacco, keeping it in top condition.

- Preservation of tobacco freshness and flavor: By creating a sealed environment, foil helps preserve the freshness, flavor, and aroma of tobacco products. It prevents the exposure of tobacco to external elements that can deteriorate its quality over time.

- Prevention of damage during transportation and storage: Foil provides a protective layer that minimizes the risk of damage during transportation and storage. It helps shield the tobacco from physical impacts, moisture, and light, maintaining its quality until it reaches the consumer.

- Role in maintaining product integrity and quality: The use of tobacco foil demonstrates a commitment to product integrity and quality. It assures consumers that the tobacco they purchase is protected and of high quality.

Types of Tobacco Foil

Tobacco foil is available in various types to cater to many kinds of tobacco product packaging needs:

- Plain tobacco foil: Plain foil is the most general type, featuring a smooth and shiny surface. It offers a clean and smooth appearance to the packaging.

- Printed tobacco foil: Printed foil can feature customized designs, logos, or branding elements. It makes tobacco manufacturers to create visually appealing packaging that aligns with their brand identity and attracts consumers.

- Different colors and designs available: Tobacco foil can be produced in different colors, such as gold, silver, or various metallic shades. This provides options for branding and difference.

- Specialized tobacco foil for specific product types: Some tobacco products require specialized foil, such as cigar wrappers or pipe tobacco foil. These foils are devised to meet the specific needs of these products, including size, thickness, and appearance.

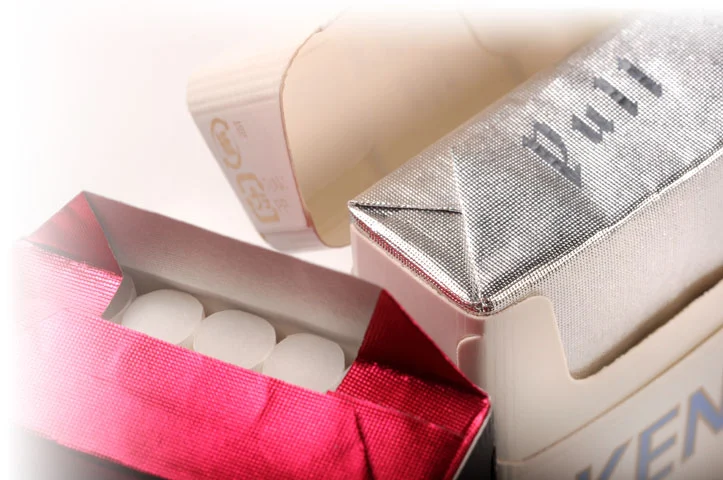

Where aluminum foil is used in cigarette packaging

Aluminum foil is used in many parts of cigarette packaging. Here are some common areas where aluminum foil is used in cigarette packaging:

Inner Wrap: Aluminum foil is commonly used as the inner wrap or lining material in cigarette packs. It is placed inside the pack to offer a barrier against moisture, light, and other external contaminants. The foil helps protect the cigarettes and preserve their freshness and quality.

Overwrap: Aluminum foil is often used as an overwrap material that covers the entire cigarette pack. It offers an additional layer of protection and acts as a barrier to maintain the freshness, aroma, and flavor of the cigarettes.

Tear Strip: Some cigarette packs feature a tear strip, which is a thin strip made of aluminum foil. It is generally located on the outer packaging and allows for easy opening of the pack by tearing along the designated line.

Hinge Foil: The hinge foil is a small strip of aluminum foil that connects the inner and outer portions of a flip-top cigarette pack. It allows the pack to open and close smoothly while maintaining the integrity of the package.

Cigarette Foil Paper: Aluminum foil is sometimes used as a component of cigarette foil paper. It is combined with other materials to create a composite paper that is used to wrap individual cigarettes. The foil layer helps protect the tobacco from external factors and ensures a consistent burn.

Manufacturing Process of Tobacco Foil

The production of tobacco foil involves several steps:

- Raw materials used in tobacco foil production: The primary raw material is aluminum, which is sourced in the form of aluminum coils or sheets. Other materials, such as paper, may be used in combination with aluminum to enhance certain properties.

- Foil rolling and annealing processes: The aluminum is processed through rolling mills to reduce its thickness and achieve the desired foil thickness. Annealing, a heat treatment process, is performed to enhance the foil’s flexibility and strength.

- Coating and printing techniques: Coatings may be applied to the foil to improve its barrier properties or add decorative effects. These coatings can include lacquers, resins, or adhesives. Printing techniques, such as rotogravure printing or flexographic printing, can be used to apply customized designs, branding elements, or product information onto the foil surface.

- Quality control measures during manufacturing: Stringent quality control measures are implemented throughout the manufacturing process to ensure the foil meets the required specifications. This includes inspection of raw materials, monitoring of thickness and weight consistency, and testing for barrier properties and heat resistance.

Safety and Regulatory Considerations

The production and use of tobacco foil are subject to safety and regulatory considerations:

- Compliance with tobacco packaging regulations: Tobacco foil must meet specific regulations and standards set by regulatory bodies governing tobacco packaging. These regulations may include requirements regarding materials, thickness, printing inks, and labeling information.

- Health and safety aspects of tobacco foil: The materials used in tobacco foil should comply with safety standards to ensure they do not pose health risks when in contact with tobacco. This includes considerations such as the absence of harmful substances or contaminants that can migrate into the tobacco.

- Impact on product quality and consumer satisfaction: The quality of tobacco foil directly affects the quality of the tobacco product. Manufacturers must ensure that the foil provides adequate protection and maintains the desired freshness, flavor, and aroma of the tobacco.

- Packaging sustainability and environmental concerns: The tobacco industry has been increasingly focusing on sustainability and reducing environmental impact. Efforts are being made to develop eco-friendly and recyclable tobacco foil options that minimize waste and resource consumption.

Innovations and Advancements in Tobacco Foil

The tobacco foil industry has witnessed several innovations and advancements:

- Introduction of eco-friendly and sustainable tobacco foil options: Manufacturers are exploring alternative materials and production processes to develop more sustainable tobacco foil options. This includes the use of recycled aluminum or biodegradable materials to reduce environmental impact.

- Technological advancements in printing and coating techniques: Advancements in printing technologies have enabled more intricate and high-quality designs to be applied to tobacco foil. Coating techniques have also improved, enhancing the foil’s barrier properties and customization options.

- Incorporation of security features to prevent counterfeiting: To combat counterfeiting and protect brand integrity, tobacco foil can incorporate security features such as holographic patterns, unique identifiers, or tamper-evident seals.

Customization options for branding and marketing purposes

Tobacco foil not only serves functional purposes in the tobacco industry but also presents opportunities for branding and marketing. Manufacturers can utilize various customization options to enhance their brand identity and appeal to consumers. Let’s explore some of the customization options available for tobacco foil:

- Printed Designs: Tobacco foil can be printed with attractive designs, patterns, logos, and brand names. This allows manufacturers to create visually appealing packaging that stands out on store shelves. By incorporating unique designs, they can differentiate their products from competitors and attract consumers’ attention.

- Colors and Finishes: Tobacco foil is available in a range of colors, allowing manufacturers to choose hues that align with their brand image. They can opt for metallic finishes, glossy or matte surfaces, or even incorporate special effects like holographic or embossed textures. These aesthetic choices contribute to the overall visual appeal of the packaging and help create a distinct brand identity.

- Branding Elements: Manufacturers can prominently display their brand logos and taglines on the tobacco foil. This helps in brand recognition and reinforces brand loyalty among consumers. Consistent branding across different products can contribute to a cohesive brand experience and facilitate consumer trust.

- Information and Messaging: Tobacco foil can also be customized to include important product information, such as health warnings, ingredient lists, or manufacturing details. This ensures compliance with regulatory requirements while providing consumers with necessary information about the product they are purchasing.

Customization options for branding and marketing purposes provide tobacco manufacturers with the opportunity to create a cohesive brand identity, attract consumers’ attention, and communicate product information effectively.

Challenges and Future Outlook

Regulatory challenges and evolving industry standards

Tobacco packaging, including tobacco foil, is subject to strict regulations and evolving industry standards. Regulatory bodies impose guidelines regarding health warnings, product labeling, packaging materials, and advertising restrictions. Manufacturers must stay updated with these requirements and ensure compliance to avoid legal issues and penalties. Additionally, as regulations continue to evolve, manufacturers may face challenges in adapting their packaging strategies to meet new standards while maintaining brand integrity.

Market trends and consumer preferences

The tobacco industry is influenced by shifting market trends and evolving consumer preferences. As consumer awareness about health risks associated with tobacco use increases, there is a growing demand for reduced-harm products and alternative nicotine delivery systems. This trend may impact the usage and demand for traditional tobacco foil. Manufacturers must stay attuned to market dynamics and consumer preferences to adapt their packaging strategies accordingly.

Potential alternatives to tobacco foil

As the industry faces environmental sustainability challenges, there is an increasing focus on finding alternatives to traditional packaging materials, including tobacco foil. Biodegradable or compostable packaging materials are being explored as potential substitutes. Manufacturers may need to invest in research and development to identify environmentally friendly solutions that can maintain the necessary barrier properties while reducing the environmental impact.

Future prospects and innovations in tobacco packaging

The future of tobacco packaging is likely to be shaped by advancements in technology, consumer demands, and regulatory developments. Innovations such as smart packaging, which incorporates electronic monitoring devices to track product authenticity and freshness, may become more prevalent. Additionally, advancements in sustainable packaging materials and manufacturing processes may lead to the development of more eco-friendly alternatives to traditional tobacco foil.

In conclusion, tobacco foil serves a vital role in the tobacco industry by providing protection, freshness, and product integrity. It offers customization options that allow manufacturers to enhance their brand identity, attract consumers, and comply with regulatory requirements. However, the industry faces challenges related to evolving regulations, shifting consumer preferences, and the need for sustainable packaging solutions.

As the tobacco industry continues to evolve, manufacturers must stay abreast of regulatory changes, market trends, and consumer demands. By embracing innovation and exploring alternative packaging materials, they can adapt to the changing landscape while ensuring the quality, safety, and appeal of their tobacco products. The future of tobacco packaging holds opportunities for advancements in technology, sustainability, and consumer engagement, shaping the industry’s direction for years to come.