Introduction

Aluminum foil can be found everywhere, it is a thin strip of aluminium and aluminium alloy with a thickness of ≤0.2mm, and its stamping effect is similar to that of pure silver foil stamping, so it is also called fake silver foil. Due to the soft texture and good ductility of aluminium, with silver-white luster, if the sheet after calendering, with sodium silicate and other substances mounted on offset paper to make aluminium foil sheet, it can also be printed. According to the use of aluminium foil can be divided into: packaging aluminium foil, air-conditioning aluminum foil, electronic aluminum foil and battery aluminum foil and so on. Have you ever wondered why aluminium is chosen over other metals to make foil?

The Historical Evolution Of Aluminum Foil

The history of aluminum foil dates back to the early 1900s, when it was originally developed for industrial applications. Its introduction as a consumer product came in the 1940s during World War II, when the lightweight metal was used to protect soldiers’ rations, and it’s worth noting that early military applications included the use of strips of aluminum foil falling from bombers to confuse and mislead radar tracking systems. Aluminum foil was so vital to defense efforts that families were encouraged to save strips of it. In many towns, it was even possible to exchange collected balls of aluminum foil for free admission to movie theaters. By the 1970s, aluminum foil and aluminum-plastic composite packaging entered a period of rapid popularity as color printing technology matured. After the 1990s, China’s aluminum foil production entered an important period, not only introducing a large number of advanced equipments, but also gradually modernizing and internationalizing the level of production management and technology development.

The Properties Of Aluminum Make It An Ideal Material For Foil Production

Lightweight And Malleable:

The density of aluminum is about 35% of that of iron and 1/3 of that of steel. It can be used to manufacture light structures and is known as “flying metal”. It can be cast by any casting method. Due to its good plasticity, it can be rolled into thin plates and foils, drawn into pipes and filaments, extruded into various profiles, forged into various parts, suitable for various cold and hot plastic forming.

Good Thermal Conductivity And Electrical Conductivity:

The thermal and electrical conductivity of aluminum is second only to gold, silver and copper, and is about three to four times that of steel. The equivalent volume conductivity of electrical aluminum at room temperature can reach 62% IACS, and if calculated according to the conductivity per unit mass, its conductivity is twice that of copper. The thermal conductivity (0~100℃) is 22.609 W/(m•K). The resistivity (20℃) is 26.7nΩ•m, and the temperature coefficient of resistance is 0.1(nΩ•m)•K-1. Manufactured into aluminum foil can be used for food cooking, grilling and so on.

Barrier Protection:

Aluminum foil has excellent barrier properties to water, air (oxygen), light, and microorganisms, and can effectively protect food from deterioration. Aluminum foil food packaging bags are high-end packaging in the food industry, with important features and advantages such as high temperature resistance, puncture resistance, and no deformation. Yongsheng Aluminum supply various grades aluminum foil: 1050, 1060, 1070, 1100, 1235, 3003, 3004, 5052, 8006, 8011, 8021, 8079 etc.

Corrosion Resistant And Non-Toxic:

When aluminum metal comes into contact with air, it can naturally form an oxide layer on the surface, which has its own corrosion resistance. This property makes aluminum foil ideal for packaging acidic or alkaline foods, as it prevents the metal from reacting with the contents, thereby maintaining the integrity and safety of the packaged items. Aluminum itself is not toxic, and its dissolution rate is very small when it comes into contact with most foods. At the same time, because the surface is smooth and easy to clean, bacteria are not easy to stay and reproduce.

Recyclability And Sustainability:

Aluminum is the most abundant metal element in the earth’s crust, and the third most common material with a wide range of sources. Aluminum foil has certain corrosion resistance, stable chemical properties, long packaging life, and can be recycled and reused. Its cycle energy consumption is only 5% of the original production, which is an economical and sustainable choice.

Aluminum Compared To Other Metals

While the properties of aluminum make it an excellent choice for foil production, there are also reasons why other metals are not suitable:

Tin: Tin was used in the past as a raw material for tin foil, but was eventually largely replaced by aluminum due to its higher cost and scarcity. Aluminum has replaced tin by offering similar performance at a more affordable price.

Copper: Copper is an excellent conductor of heat, but lacks the same corrosion resistance as aluminum. It can react with certain foods, causing potential health problems.

Steel: Steel is durable and strong, and much heavier than aluminum. Although aluminum is not as strong as steel, it is far more flexible and ductile than steel, which is why aluminum foil can be made very thin.

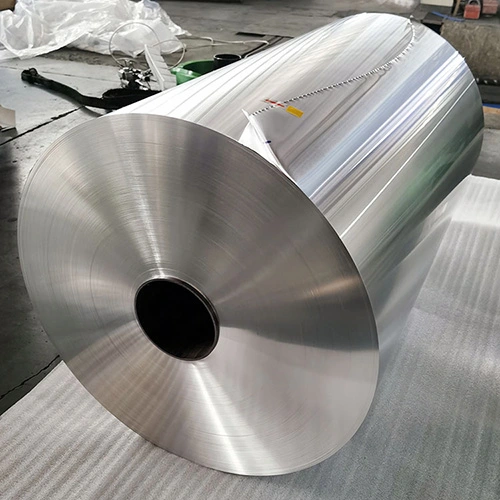

Yongsheng Signature Aluminum Foil

1235 aluminum foil

The aluminum content of 1235 aluminum foil is not less than 99.35%. Yongsheng Aluminum can process 1235 aluminum foil with a thickness of 0.006-0.2mm. This product is widely used in cables because of its excellent antirust properties, formability, and weldability. tape, battery foil.

8011 aluminum foil

8011-H18 aluminum foil and 8011-O aluminum foil substrate are our company’s superior products. Yongsheng Aluminum can process 8011 aluminum foil with a thickness of 0.006-0.2mm. This aluminum foil is mainly used in pharmaceutical packaging, food packaging, aluminum foil tape, cable tape, aluminum bottle cap and other fields, and this grade can also be customized according to customer needs.

8021 aluminum foil

The thickness range of 8021 aluminum foil is 0.006mm-0.2mm, and the width can be controlled at 100-1600mm according to customer requirements. 8021 aluminum foil is the main product of food packaging and battery soft packaging aluminum foil. 8021 aluminum foil has excellent moisture-proof performance, light-shielding and extremely high barrier ability. Non-toxic and tasteless, safe and hygienic. Aluminum foil after compounding, printing and gluing is widely used as packaging material.

During the production process, 8021 aluminum foil has passed multiple tests such as bacteria and mold. The content of heavy metals must not exceed 0.25ppm to ensure that the finished product is non-toxic, tasteless, safe and hygienic. Therefore, 8021 aluminum foil is often used as medicinal aluminum foil, Use aluminum foil for packaging.

8079 aluminum foil

8079 aluminum foil is an aluminum foil with high strength, good elongation and stretchability. The 8079 aluminum foil produced by Yongsheng has multiple advantages such as food grade, clean oil removal, less pinholes, good product shape, and no deformation when cutting.

Conclusion

In summary, aluminum is a lightweight metal with good thermal conductivity and corrosion resistance, which make it an ideal material for manufacturing aluminum foil. The chemical properties of aluminum also influence the production of aluminum foil, such as its good plasticity and malleability, which allows the aluminum block to be cold rolled or hot rolled into a variety of different thicknesses of aluminum foil, and low rheological stress, which makes it easy to be stretched by rolls to form thin sheets. Together, these chemical properties make aluminum a tough, flexible and durable foil. Whether in everyday cooking, medicine, industry, construction or many other areas, you can find aluminum foil.