In modern industrial and decorative applications, mirror finish aluminum is highly favored for its excellent reflective properties and aesthetic appeal. However, the variety of mirror finish aluminum available on the market can be overwhelming, with varying quality levels. This guide will cover eight key aspects to consider when selecting high-quality mirror finish aluminum: surface quality, material and specifications, reflectivity, protective film and packaging, machining performance, environmental and safety considerations, supplier reputation, and price and service.

Surface Quality

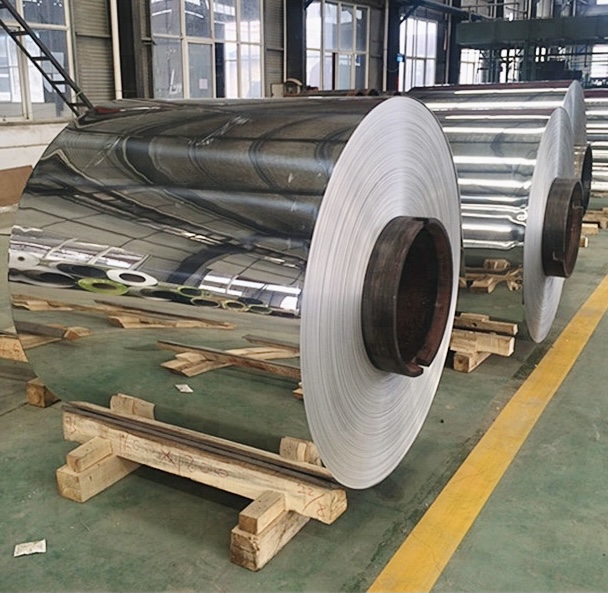

Surface quality is the most critical factor in selecting mirror finish aluminum. High-quality mirror finish aluminum should have a flat, smooth surface without noticeable scratches, defects, or warping. Before purchasing, check the flatness of the aluminum sheet to ensure it is free from bends or ripples. If the aluminum surface has a coating, make sure it is uniform and free from bubbles, cracks, or peeling. Surface quality directly affects the reflective performance and visual appeal of the aluminum, making it essential for showcasing product quality.

Material and Specifications

The material and specifications of mirror finish aluminum are also vital. Mirror finish aluminum typically comes in various aluminum alloy grades, such as 1050, 1060, and 1070. The different purities and compositions affect the material’s performance and suitability for specific applications. Choose the appropriate thickness and size specifications based on your actual needs to ensure optimal application results. Generally, thicknesses can range from 0.3 mm to 3 mm, so specify based on your requirements.

Reflectivity of Mirror Finish Aluminum

Reflectivity is a key indicator of the performance of mirror finish aluminum. The higher the reflectivity, the better the clarity and brightness of the mirror, resulting in a more effective application. High-quality mirror finish aluminum typically has a reflectivity of 85% to 95%. When selecting a product, pay close attention to the parameters to confirm that its reflectivity meets your expectations.

Protective Film and Packaging

Mirror finish aluminum is usually covered with a protective film to prevent scratches and damage during transportation and handling. When selecting, ensure that the protective film is intact and easy to remove. In terms of packaging, opt for products that are properly packaged to facilitate transport and storage, thus avoiding damage during handling.

Machining Performance

Depending on your specific application needs, the machining performance of mirror finish aluminum should also be considered. If secondary processing such as cutting, bending, or stamping is required, choose materials that offer good machinability. Different aluminum alloys have varying levels of processing difficulty and results, so evaluate options based on your specific processing requirements.

Environmental and Safety Considerations

Environmental and safety factors are also crucial, particularly in applications where health and environmental regulations are strict, such as in the food and medical industries. Ensure that the mirror finish aluminum you select complies with relevant environmental and safety standards to avoid using materials that contain harmful substances.

Supplier Reputation

When selecting a supplier, consider their reputation and credibility. Reputable suppliers typically have strict quality control systems in place, allowing them to provide stable and high-performance products. Assess potential suppliers’ reliability and credibility by reviewing customer feedback and industry certifications, helping you choose a trustworthy partner.

Price and Service

Price and service are important aspects to consider in the selection process. Compare prices from different suppliers to understand market trends and find reasonably priced, reliable quality products. Additionally, pay attention to the after-sales services offered by suppliers; quality after-sales support can provide necessary technical assistance and problem resolution during product use.

Conclusion

Selecting quality mirror finish aluminum requires a comprehensive evaluation of multiple factors, from surface quality to material specifications and reflectivity to machining performance. By carefully considering these aspects, you can choose the right mirror finish aluminum that meets your needs, ensuring excellent performance and durability in specific applications. We hope this guide provides valuable insights, helping you make informed decisions when selecting mirror finish aluminum for your projects!