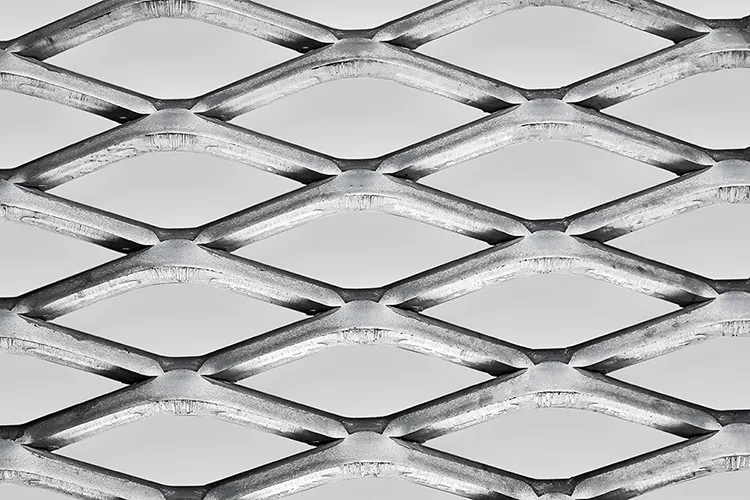

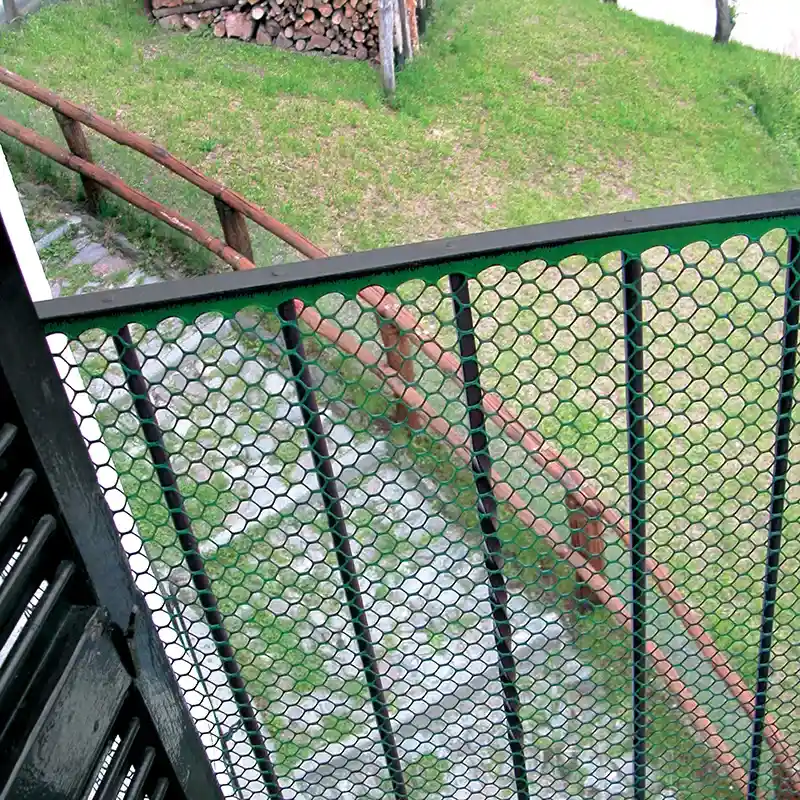

Aluminum mesh sheet is also called aluminum mesh. It is made of an aluminium plate that is expanded and stretched by a machine. Its mesh body is lighter and has strong load-bearing capacity. Metal aluminum mesh panels are mainly composed of mesh panels and frames. The size and shape of the mesh panel grid can be customized. The frame structure is designed to facilitate installation. It is generally a hook-type frame, and the square frame is equipped with hanging ears (corner codes) . The most common aluminum mesh has diamond-shaped holes, and other hole types include hexagonal, round, triangular, fish-scale holes, etc. Mainly used for house decoration, handicraft production, high-end speakers, ceilings, etc. You can see it in subways, airports, stations, passages, large shopping malls, exhibition centers and other places. It also has many aliases, like:

Aluminum metal mesh sheet

Aluminum stretch metal mesh

Expanded aluminum sheet

Aluminum mesh metal sheets

Alu mesh

Expanded sheet aluminum

Characteristics Of Aluminum Mesh Sheet:

Corrosion resistance: The formation of an oxide layer on aluminum prevents further oxidation and corrosion. Aluminum alloys such as 6061 aluminium and 5052 aluminum show good corrosion resistance in most common environments.

Thermal conductivity: Aluminum has a thermal conductivity of approximately 237 W/m·K and is very popular in many thermal conductivity applications, such as radiators, heat exchangers, etc.

Conductivity: Pure aluminum has a conductivity of approximately 37.7 MS/m. It is worth noting that the electrical conductivity of aluminum alloys with different alloy compositions or treatments may vary.

Strength: The strength of aluminum mesh sheet depends on many factors, including the material properties of the aluminum alloy, mesh structure, wire diameter and mesh size, etc. Research shows that the tensile strength of 6061-T6 aluminum alloy is approximately 276 MPa and the yield strength is approximately 240 MPa. Different alloys and processing conditions will produce different strength values; the mesh structure of the aluminum mesh also affects its strength. Generally, the denser the mesh, the stronger the aluminum mesh; the wire diameter is also an important factor in determining the strength of the aluminum mesh. Larger diameter wires generally have higher strength. For example, the tensile strength of duralumin mesh with a diameter of 0.25 mm is approximately 90 MPa.

Advantages Of Aluminum Mesh Sheet:

- Light Weight.

- High Hardness.

- Preservative.

- High Temperature Resistant And Fireproof.

- Uniform Mesh.

- Can Be Coated.

- Transparency.

- Plasticity.

- Non-Toxic.

- Good Appearance.

Aluminum Mesh Sheet Manufacturing Process:

1.Material preparation: Common ones include 1100 aluminum sheet, 3003 aluminum sheet, 5052 aluminum sheet, etc.

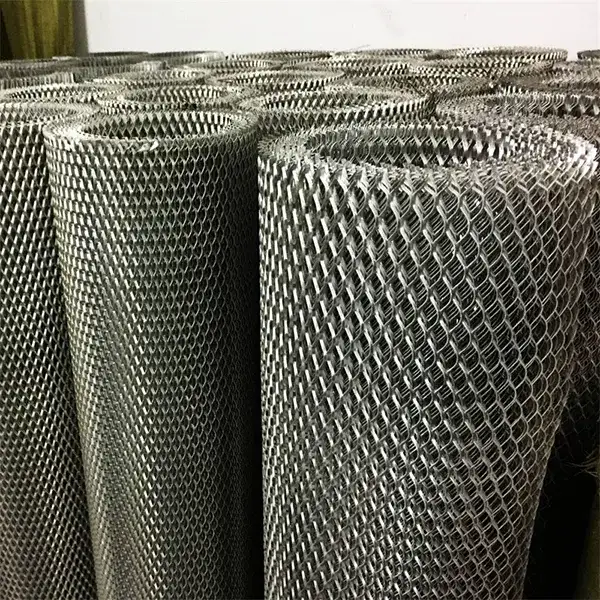

2.Stretching: According to the requirements of the product, the aluminum material is stretched using stretching equipment. That is, the aluminum plate or aluminum coil is stretched into a mesh structure, and the shape of the aluminum mesh is determined by the customer. Guaranteed stability of mesh size, mesh shape and mesh structure during the stretching process and customer satisfaction.

3.Processing/Punching/Welding: According to the specific requirements of the aluminum mesh sheet, processing procedures such as punching or welding are performed. Punching is the punching of holes on the aluminum plate through a mold, which can form holes of different shapes and sizes. Welding refers to connecting aluminum plates or bars through a welding process to form a grid structure.

4.Packaging/Shipping: After completion of manufacturing and inspection, the aluminum mesh needs to be properly packaged and labeled to ensure that it is not damaged during transportation. Common packaging methods include wooden boxes, pallets, etc. Choose the appropriate packaging method according to the specific situation.

Applications of Aluminum Mesh Sheets:

Screens And Filters

Architecture And Decoration

Furniture Manufacturing

Electronic Product

Horticulture And Agriculture

How To Clean And Maintain Metal Alu Mesh Sheets:

Clean:

You can use a soft-bristled brush or vacuum cleaner to gently clean the surface of the aluminum mesh sheet. Avoid scratching with hard objects or sharp tools to avoid damaging the mesh.

If the aluminum mesh is contaminated with sticky stains or grease, you can gently wipe it with warm water and mild detergent, and then dry it with a clean cloth. Be careful not to use highly corrosive chemical cleaners.

Maintain:

Regularly check whether the structure and connections of the aluminum mesh are firm. If there is any looseness or damage, repair or replace it in time to ensure the stability and safety of the aluminum sheet mesh.

If corrosion is found on the expanded aluminum sheet, it can be treated with aluminum mesh protective agent to form a protective film and extend the service life of the aluminum mesh.

According to different seasons and environments, it is recommended to carry out regular anti-corrosion coating treatment on outdoor aluminum sheets mesh to increase its anti-oxidation and anti-corrosion properties.

Precaution:

Avoid stacking sharp objects or heavy objects near the aluminum mesh to avoid accidental scratches or deformation.

Avoid contact of the aluminum mesh metal sheets with acidic, alkaline or corrosive liquids to avoid damaging the surface of the aluminum mesh sheets.

In heavy rain, snowstorm or severe weather conditions, try to avoid long-term exposure of aluminum mesh sheets to extreme conditions. You can consider installing awnings or other measures for protection.

Popularization of Metal Mesh Knowledge:

Metal mesh materials are generally aluminum alloys, stainless steel, copper, etc. with good weather resistance. They are often used in protective nets, walls, fences, etc. in construction projects. At present, metal mesh materials are widely used in the field of indoor landscape art installations in buildings. As maintenance partitions, stair railings, decorative materials, furniture materials, etc. Metal mesh materials are divided into three categories in terms of processing:

- Woven wire mesh – metal mesh and metal mesh curtains made of metal wires, wires and strands woven by machines.

- Stretched expanded metal – made of metal sheets as raw materials through mechanical cutting, stretching, pressing and other processes.

- Welded wire mesh – made of metal wires welded by special methods.

Aluminum Screen Cost and Availability:

The production process and raw material costs of aluminum mesh panels will affect the cost of aluminum mesh. In addition, generally larger size and thicker aluminum mesh will be relatively more expensive, and the kind that requires special custom aluminum mesh, such as a specific geometry, aperture or grid pattern will usually be more expensive than standard specifications because They require additional processing fees.

Aluminium Perforated Metal Sheet vs Aluminum Mesh Sheet:

There are big differences in the manufacturing process between the two, as shown in the following: Aluminum plate punching mesh is a metal mesh that uses a punch to punch aluminum plates to form various patterns. Aluminum stretched metal mesh is a metal mesh with simple patterns such as rhombus holes and hexagonal holes that is expanded and stretched by a steel mesh machine.

Aluminium perforated metal sheet: Perforated aluminum sheet usually has a high opening ratio, which can provide good ventilation and light transmission. It is often used in architectural decoration, filters, protective covers, etc. It can also be used as a design element in interior decoration. Perforated aluminum sheets pay more attention to their appearance and functionality in their applications.

Aluminum mesh sheet: Due to its special structure, expanded aluminum sheet has high strength and rigidity and can withstand large loads. Therefore, aluminum stretch metal mesh is often used in situations where load-bearing and anti-slip properties are required, such as stair treads, platform paving, suspended ceilings, etc.

FAQ:

What Is The Thickness Of Aluminum Mesh Sheet?

The thickness of aluminum mesh metal sheets refer to the thickness of the mesh, which is the diameter of the aluminum wire or the thickness of the mesh. Commonly used aluminum plate mesh thickness ranges are: 04mm-1.0mm 0.8mm-1.0mm 0.3mm-1.5mm 0.1mm-9mm, etc. Yongsheng can customize the thickness of aluminum metal mesh sheet of various alloys to ensure that it meets your needs.

Does Aluminium Mesh Rust?

No, aluminum mesh metal sheets will not rust. Unlike iron or steel, aluminum is a non-ferrous metal, which means it does not contain iron and does not rust easily. Rust is a chemical reaction that occurs when iron or steel comes into contact with moisture and oxygen. Aluminum forms a natural oxide layer on its surface when exposed to air, which prevents corrosion. This oxide layer acts as a barrier, preventing further oxidation and rusting of the metal. Therefore, aluminum mesh has strong rust and corrosion resistance, making it suitable for a variety of applications, including outdoor use.

What Is The Strongest Metal Mesh?

Strong metal mesh is made from materials such as stainless steel, titanium, and tungsten. Stainless steel mesh is widely used and is known for its strength, corrosion resistance and durability. Titanium mesh is known for its excellent strength-to-weight ratio and corrosion resistance. Tungsten mesh is very strong and has excellent heat resistance.