Introduction of Building Materials

Building materials for exterior walls play a crucial role in the construction of durable and aesthetically appealing structures. The selection of the right materials is key to ensuring the longevity, energy efficiency, and overall performance of the building. This comprehensive guide examines various building materials commonly used for exterior walls, highlighting their unique characteristics and benefits in creating resilient and visually pleasing facades.

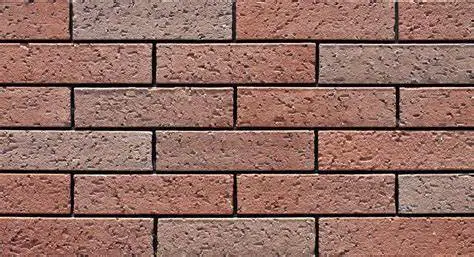

Brick: A Timeless Choice for Building Materials

Brick has long been a favored building materials for exterior wall due to its timeless appeal and durability. Its natural composition and manufacturing process make it an eco-friendly option. Brick offers excellent thermal insulation, contributing to energy efficiency and reducing heating and cooling costs. With its wide range of colors, textures, and patterns, brick provides versatility in design, allowing for customization to suit different architectural styles.

Concrete: Strength and Versatility

Concrete is a versatile and widely used building materials for exterior walls. Its strength and durability make it ideal for withstanding various weather conditions and providing structural stability. Precast and cast-in-place concrete walls offer design flexibility and can be customized to meet specific project requirements. Additionally, concrete walls provide excellent fire resistance, ensuring the safety of the building and its occupants.

Stone: A Premium Choice for Elegance and Durability

Natural stone is renowned for its elegance and durability, making it a premium option for building materials. Stone walls offer exceptional weather resistance, enduring even the harshest climates. The unique textures and colors of different types of stone, such as granite, limestone, and sandstone, provide an unmatched natural aesthetic. Stone is a low-maintenance material that ages gracefully, adding character and charm to any building.

Metal: Lightweight and Modern

Metal has gained popularity as a modern and contemporary choice for exterior walls. Aluminum, in particular, offers numerous advantages. Its lightweight nature eases installation, reduces structural requirements, and enables faster construction. Aluminum’s corrosion resistance ensures longevity, making it suitable for coastal areas and regions with high humidity. Moreover, aluminum sheets can be easily fabricated, allowing for intricate designs and shapes that enhance the visual appeal of the building.

Common Aluminum Sheet Models

- 6061 Aluminum sheets: 6061 aluminum sheet is a generally used material for building exteriors. It has fantastic hardness 6061 aluminum sheets also has good workability and can be cut, bent and welded to satisfy the needs of various building designs.

- 5052 Aluminum sheets: 5052 Aluminum sheets is also a general material for building exteriors. It has fantastic hardness and good anti-rust characteristics, and can prevent the erosion of humidity and chemicals. 5052 aluminum sheets appearance can be sprayed and oxidized to improve its weather resistance and decorative effect.

- 3003 Aluminum sheets: 3003 Aluminum sheets is a commonly used aluminum sheets type for exterior building uses. It has good anti-rust characteristics and malleability, and is easily machined into many kinds of shapes and sizes. 3003 aluminum sheets also has high strength and good welding characteristics, allowing it suitable for exterior wall panels.

- 6063 Aluminum sheets: 6063 Aluminum sheets is generally used in the producing of aluminum profiles for building facades. It has good malleability and appearance treatment characteristics, allowing for complicated shapes and modeling needs. 6063 aluminum sheets also has anti-rust characteristics and a certain degree of strength, making it suitable for the producing of exterior curtain walls and decorative materials.

Common Advantages of these aluminum sheet models

- Lightweight: Aluminum alloys have a low density, making them lightweight compared to other building materials. This characteristic eases handling and installation while reducing structural loads on the building.

- Corrosion Resistance: Aluminum alloys possess inherent corrosion resistance, even without additional coatings. This makes them suitable for exterior uses where exposure to moisture, humidity, and harsh weather conditions is common.

- Design Flexibility: Aluminum alloys can be easily formed and extruded into various shapes, allowing for creative and versatile design possibilities. They can be customized to fit specific architectural requirements, resulting in visually appealing exteriors.

- Durability: Aluminum alloys have excellent durability and longevity. They can stand exposure to UV radiation, temperature fluctuations, and environmental pollutants without significant degradation, making sure the longevity of the building’s exterior.

- Low Maintenance: Owing to their corrosion resistance and durability, aluminum alloy exteriors require minimal maintenance. They do not require frequent painting or sealing, reducing long-term maintenance costs.

- Recyclability: Aluminum alloys are highly recyclable, allowing for sustainable construction practices. They can be easily recycled and reused without loss of quality, contributing to environmentally friendly building practices.

- Thermal Performance: Aluminum alloys can be designed with thermal breaks or insulation to enhance energy efficiency. This helps in reducing heat transfer through the walls, improving the building’s overall thermal performance.

Comparison of advantages and disadvantages of different aluminum alloys as building exterior walls

| Aluminum Alloy | Advantages | Disadvantages |

| 6061-T6 | – High strength-to-weight ratio – Good corrosion resistance – Formability and machinability | – Relatively higher cost compared to other alloys – Limited color options |

| 5052-H32 | – Excellent corrosion resistance – Good formability and weldability – Lower cost compared to 6061 | – Lower strength compared to 6061 – Limited availability in certain regions |

| 3003-H14 | – Cost-effective option – Good corrosion resistance – Suitable for general-purpose applications | – Lower strength compared to 6061 and 5052 – Limited color options |

| 1100-H14 | – Highly malleable and easy to work with – Good corrosion resistance – Lower cost | – Lower strength compared to other alloys – Limited availability in certain regions |

| 3004-H32 | – Enhanced strength compared to 3003 – Good corrosion resistance – Suitable for painted finishes | – Limited availability in certain regions – Higher cost compared to 3003 |

Specific Applications of Aluminum Alloy in Building Materials

Aluminum alloys are extensively used in building facades owing to their versatility, durability, and aesthetic appeal. Here are some specific applications of aluminum alloy in building facades:

- Curtain Wall Systems: Aluminum alloy is generally used in curtain wall systems, which are non-load-bearing exterior cladding systems. Aluminum profiles and panels are used to create a lightweight and visually appealing façade that offers weather protection, thermal insulation, and soundproofing.

- Window Frames and Glazing Systems: Aluminum alloys are popular options for window frames and glazing systems in building facades. They offer strength, durability, and excellent thermal performance. Aluminum profiles can be designed to accommodate different types of glass, such as double-glazed or Low-E glass, providing energy efficiency and sound insulation.

- Cladding Panels: Aluminum alloy cladding panels are used to create decorative and protective exterior surfaces. These panels can be custom-designed and fabricated to achieve many kinds of textures, colors, and shapes. Aluminum cladding panels are lightweight and weather-resistant, providing an attractive and low-maintenance solution for building facades.

- Louvers and Sunshades: Aluminum louvers and sunshades are generally used as architectural functions in building facades. They offer shading, glare reduction, and natural ventilation while improving the aesthetic appeal of the building. Aluminum’s lightweight nature and corrosion resistance make it suitable for these applications.

- Decorative Elements: Aluminum alloys are used for decorative elements in building facades, such as ornamental screens, perforated panels, and trims. These elements can add visual interest, texture, and depth to the façade design while allowing for airflow and light penetration.

- Column Covers and Canopies: Aluminum alloy is often used to create column covers and canopies in building facades. These elements offer protection, improve the building’s architectural style, and contribute to the comprehensive aesthetics of the façade.

Wood: Warmth and Natural Beauty

Wood has a timeless appeal and provides a warm and natural aesthetic for building materials. It offers natural insulation properties, reducing heat transfer and energy consumption. Wood is a renewable resource, making it an environmentally friendly choice. With proper treatment and maintenance, wood walls can withstand the elements and retain their beauty for decades. However, it is important to address concerns such as moisture, pests, and fire protection through appropriate treatment and sealing.

Fiber Cement: Durability and Low Maintenance

Fiber cement is a versatile and low-maintenance option for exterior walls. Composed of cement, sand, and cellulose fibers, it offers exceptional durability, moisture resistance, and fire resistance. Fiber cement panels are available in various textures and can mimic the appearance of wood or stone, providing design versatility. Additionally, fiber cement requires minimal maintenance, making it a cost-effective option over the long term.

Composite Materials: Innovative Solutions for Strength and Design

Composite materials combine different elements, such as aluminum, fiberglass, or polymers, to create innovative alternatives for building materials. These materials offer enhanced strength, durability, and customization options. Aluminum-based composites, for instance, provide lightweight yet sturdy solutions for contemporary designs. Composite materials open up possibilities for unique architectural expressions while maintaining structural integrity and performance.

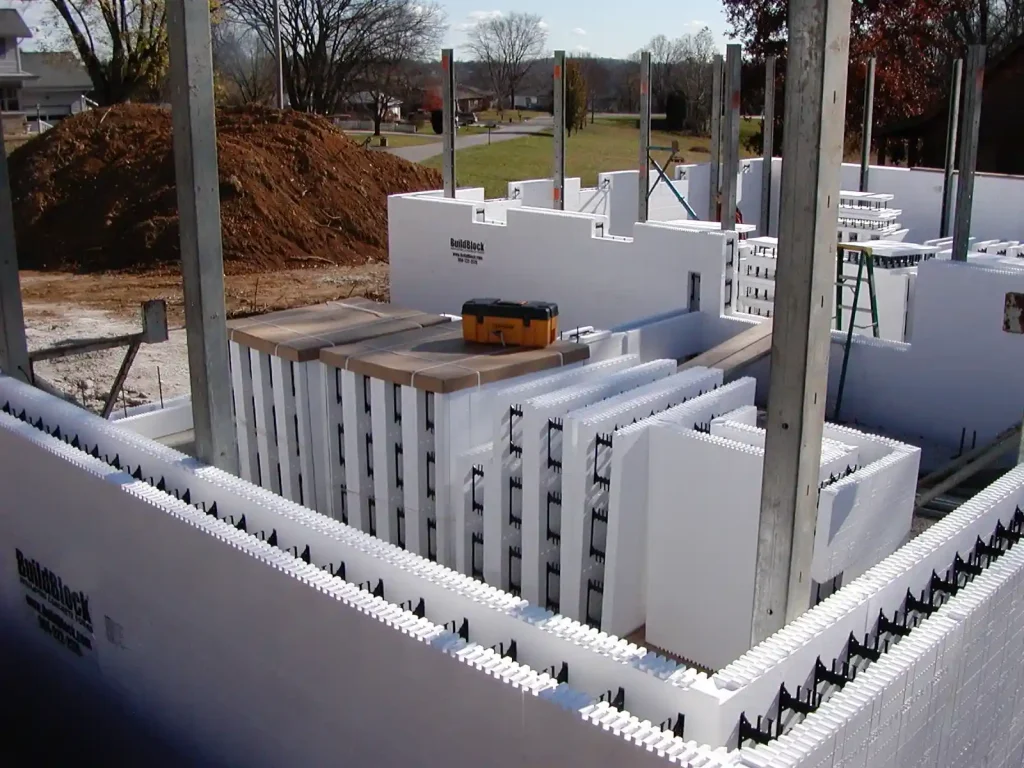

Insulated Concrete Forms (ICFs): Energy Efficiency and Structural Strength

Insulated Concrete Forms (ICFs) combine insulation and structural support for exterior walls. These forms, typically made of expanded polystyrene or polyurethane foam, offer excellent energy efficiency, sound insulation, and durability. Aluminum-based ICF systems enhance the structural integrity of the walls while providing the benefits of aluminum’s lightweight nature and corrosion resistance. ICFs contribute to energy savings by reducing heat loss or gain, resulting in lower energy consumption and increased comfort.

Summary

Choosing the right building materials for exterior walls is essential for creating durable, aesthetically pleasing, and energy-efficient structures. Brick, concrete, stone, metal (including aluminum), wood, fiber cement, composite materials, and ICFs each offer unique characteristics and advantages. By carefully considering the specific requirements, climate conditions, design preferences, and maintenance considerations, architects, builders, and homeowners can make informed decisions to achieve the desired balance of durability, aesthetics, and sustainability in their exterior wall systems.

FAQ

What is the most durable cladding?

Vinyl cladding or PVC cladding is a very durable external cladding material. It is also affordable, lightweight, and low maintenance.

What are exterior wall coatings?

You can cover the walls outside your house or place of business with an outside wall coating. They may be applied to masonry, existing render, and a variety of other surfaces and are significantly thicker than any sort of exterior paint.