Understanding and Calculating the Weight of a 4×8 Aluminum Sheet

Aluminum sheets are widely used in various industries due to their lightweight yet durable nature. Whether you are a professional in the construction, automotive, or aerospace industry, or simply a DIY enthusiast, understanding how to calculate the weight of a 4 x 8 aluminium sheet is an essential skill. This knowledge not only aids in material planning but also ensures the structural integrity of projects. In this article, we will delve into the intricacies of aluminum sheet weight calculation, considering different factors that can influence the final result.

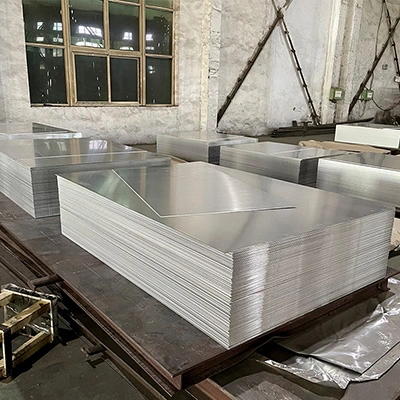

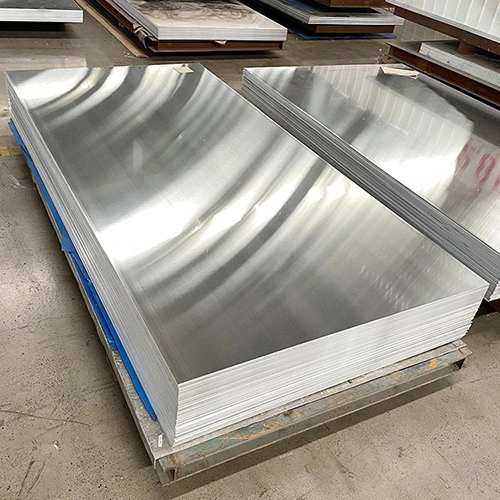

The Basics of Aluminum Sheets

Sheets aluminum come in various sizes and thicknesses, making them adaptable for an array of applications. A common size is the 4’x8′ feet sheet, which is widely used due to its compatibility with standard construction dimensions. The term “4×8” refers to the sheet’s dimensions in feet – 4 feet in width and 8 feet in length. However, the weight of an aluminum sheet is influenced not only by its dimensions but also by its thickness.

Factors Affecting Weight Calculation

1. Aluminum Alloy

Aluminum sheets are available in a range of alloys, each with distinct properties and compositions. Different alloys have varying densities, which directly impact the weight of the sheet. For instance, the density of 1100 aluminum alloy is around 0.098 pounds per cubic inch (lb/in³), while the density of 6061 aluminum alloy is approximately 0.098 lb/in³. It’s crucial to identify the specific alloy you are working with to ensure accurate aluminium weight calculations.

2. Sheet Thickness

The thickness of an aluminum sheet plays a significant role in determining its weight. Thicker sheets contain more material and thus weigh more. Aluminum sheets are typically measured in gauge or millimeters. The gauge number decreases as the sheet gets thicker. For instance, a 10-gauge aluminum sheet is thicker than a 12-gauge aluminum sheet. Converting the gauge measurement to millimeters is essential for accurate calculations.

3. Density

The density of a material is defined as its mass per unit volume. For aluminum, the density is relatively low compared to other metals, which contributes to its lightweight nature. The density of aluminum is typically around 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³). This value is consistent regardless of the alloy.

4. Surface Finish

The surface finish of the aluminum sheet can also influence its weight slightly. Different surface treatments and coatings can add a minimal amount of weight, but this effect is generally negligible for most applications.

Calculating the Weight

The formula to calculate the weight of an aluminum sheet is straightforward:

Weight = Length × Width × Thickness × Density

However, there are a few considerations to keep in mind when using this formula:

- Consistent Units: Ensure that all measurements are in the same units. If the length and width are in feet, the thickness should also be in feet (or converted to the appropriate unit, such as inches).

- Thickness Conversion: Convert the thickness from gauge to a consistent unit of measurement. The gauge-to-millimeter conversion can vary, so it’s important to use an accurate conversion factor.

- Density: Use the correct density value for aluminum, which is around 2700 kg/m³ or 0.098 lb/in³.

- Precision: Depending on the precision of your measurements and the desired accuracy of the result, you may need to round off the final weight value.

Example Calculation

Let’s walk through an example calculation for a 4′ x 8′ aluminum sheet:

- Dimensions: Length = 8 feet, Width = 4 feet

- Thickness: 12-gauge aluminum sheet (approx. 0.0808 inches or 2.05 mm)

- Density: 0.098 lb/in³ or 2700 kg/m³

Using the formula:

Weight = 8 ft × 4 ft × 0.0808 in × 0.098 lb/in³

Calculating further:

Weight ≈ 25.214 lb (pounds)

In metric units:

Weight ≈ 11.45 kg (kilograms)

Conclusion

Knowing how to calculate the weight of a 8 x 4 aluminum sheet is an essential skill for professionals and enthusiasts alike. By understanding the factors that influence the weight – including alloy, thickness, and density – you can accurately plan and execute projects, ensuring that structural requirements are met without overloading the intended application. Remember that precision in measurements and unit conversions is key to obtaining accurate weight calculations. With this knowledge in hand, you can confidently work with aluminum sheets in various industries and projects.