Aluminum Circle For Spinning

Category Aluminum Circle

Alloy: 1000, 3000, 5000, 6000 series, etc

Temper: O-H112, etc

Width: 50mm-1600mm, Customized

Thickness: 0.2 mm- 8 mm

Surface Treatment: Mill finish, coating

Applications: Suitable for making pots, pans, pizza pans, pie plates, cake pans, lids, kettles, basins, fryers, reflectors.

Aluminum Circle Spinning Process Description:

Aluminum circle for spinning forming relies on the feed motion of tools such as rotating wheels to pressurize the aluminum circle blank that rotates together with the machine spindle, causing it to undergo continuous local plastic deformation and become part of the required hollow rotary body parts. There are few types and no cutting processing technology.

Specifications and Technical Parameters of Spinning Aluminum Circle:

|

Name |

Alloy | Purity | Temper | Thickness(mm) |

Diameter(mm) |

|

Aluminum Circle Disc |

1050,1060,1070,3003 |

96.95%-99.70% |

O, H12, H14 |

0.5-4.5 |

90-1020 |

Aluminum Circle Mechanical Properties:

|

Temper |

Thickness(mm) | Tensile Strength(MPa) | Elongation(%) | Tolerance |

|

O |

0.4-6.0 | 60-100 | ≥20 |

±1% |

| H12 | 0.5-6.0 | 70-120 |

≥4 |

|

| H14 | 0.5-6.0 | 85-120 |

≥2 |

Characteristics of Aluminum Circles for Spinning:

- Economical and low cost.

- Product quality guaranteed.

- Exact dimensions.

- Good thermal conductivity.

YSA Aluminum Circles Factory:

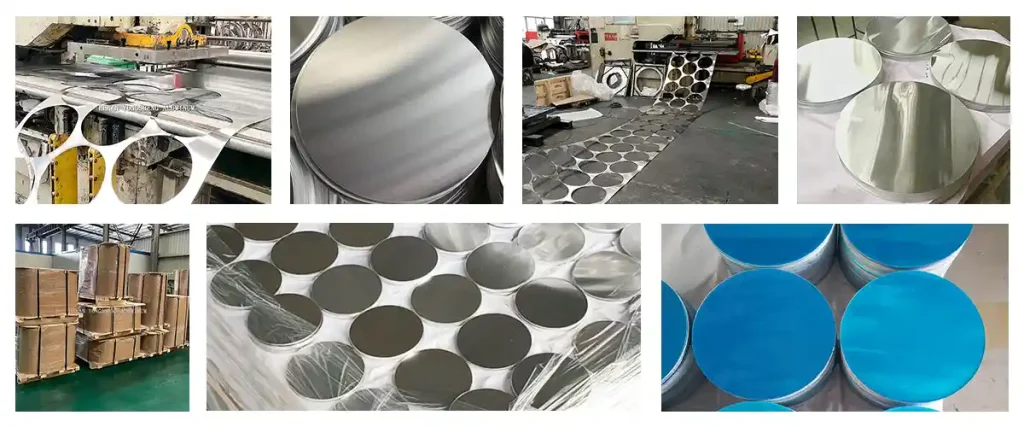

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes

Category Aluminum Circle