Aluminum Sheet For PS Printing Plate

Alloy: 1050, 1060, 1070 series

Temper: O H14 H24 H18 H22 H32, etc

Width: 100mm-2600mm

Thickness: 0.1 mm- 350 mm

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

Price Terms: FOB, CIF, CFR, CNF, etc.

What Is Aluminum Sheet For PS Printing Plate?

Aluminum sheet for PS printing plate, sometimes referred to as newspaper plate, printed zinc plate, or advertising aluminum plate, is aluminum with a printed pattern on the back that has a thickness of 0.25 or 0.3 mm.Aluminum sheet for PS printing plate is a lithographic aluminum plate substrate that has been pre-coated with a layer of photosensitive resin. The PS aluminum substrates with an aluminum composition of more than 99% are the 1050, 1060, and 1070 alloys that are most frequently utilized.

Chemical Properties Of Advertising Aluminum Plate

| Al | Si | Cu | Mg | Zn | Mn | Cr | Fe |

| allowance | 0.25 | 0.1 | 2.2-2.8 | 0.1 | 0.1 | 0.15-0.35 | 0.4 |

Mechanical Properties Of PS Aluminum Sheet

| Tensile strength (σb) | Conditional yield strength σ0.2 (MPa) | Elastic modulus (E) | Annealing temperature |

| 170~305MPa | ≥65 | 69.3~ 70.7gpa | 345℃ |

The Production Process of Aluminum Sheet for PS Printing Plate

- Aluminum Ingot Preparation: The production begins with the preparation of high-quality aluminum ingots. The ingots are usually made from aluminum alloy, which is carefully selected based on its purity and desired properties.

- Homogenization: The aluminum ingots undergo a homogenization process to ensure uniformity in composition and structure. This step involves heating the ingots to a specific temperature and holding them for a set period. It helps to eliminate any chemical segregation or structural inconsistencies within the material.

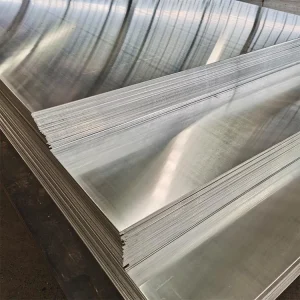

- Hot Rolling: The homogenized aluminum ingots are then heated and passed through a series of rolling mills. This process, known as hot rolling, reduces the thickness of the aluminum and increases its length. The aluminum is continuously heated and rolled until it reaches the desired thickness.

- Cold Rolling: After hot rolling, the aluminum strip is further processed through cold rolling. Cold rolling involves passing the strip through a series of rollers at room temperature. This step refines the thickness and surface finish of the aluminum sheet, improving its dimensional accuracy and mechanical properties.

- Annealing: The cold-rolled aluminum sheet may undergo an annealing process to relieve internal stresses and improve its formability. Annealing involves heating the aluminum sheet to a specific temperature and then gradually cooling it. This step helps to enhance the material’s strength, ductility, and stability.

- Surface Treatment: The aluminum sheet is subjected to surface treatment to ensure optimal printability and adhesion of photosensitive materials. This treatment typically involves processes such as degreasing, etching, and anodizing. Degreasing removes any residual oils or contaminants from the surface, while etching creates a micro-roughened texture to enhance ink adhesion. Anodizing forms a protective oxide layer on the surface, improving corrosion resistance.

- Cutting and Shearing: The aluminum sheet is cut into standard sizes or customized dimensions using cutting and shearing machines. This step ensures that the sheets are ready for further processing or packaging according to customer requirements.

- Quality Control: Throughout the production process, rigorous quality control measures are implemented to ensure that the aluminum sheets meet specific industry standards and customer specifications. This includes inspections for thickness, flatness, surface quality, and other mechanical properties.

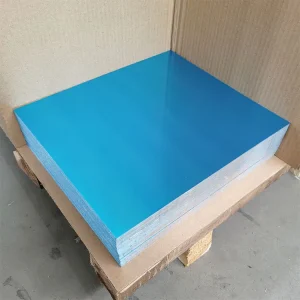

- Packaging and Distribution: After the production process, the aluminum sheets go through packaging and distribution. This final step aims to safeguard the sheets from any potential harm that may occur during their transportation and storage. Typically, the sheets are carefully wrapped using protective materials and then bundled together. Subsequently, they are shipped to customers or distribution centers.

The Applications of Aluminum Sheet for PS Printing Plate

| Application | Description |

| Commercial Printing | Printing magazines, brochures, catalogs, posters, and promotional materials. |

| Packaging Printing | Printing labels, folding cartons, flexible packaging, and corrugated boxes. |

| Newspaper Printing | Printing newspapers with high-speed production requirements. |

| Label Printing | Printing barcode labels, product information labels, and brand labels. |

| Security Printing | Printing security documents like banknotes, passports, identity cards, and security labels. |

| Promotional Materials | Producing banners, posters, POP displays, and signage for advertising and marketing purposes. |

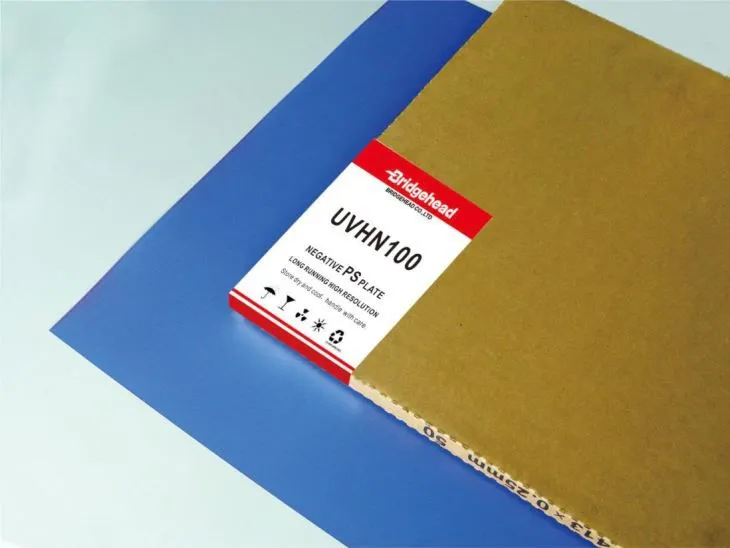

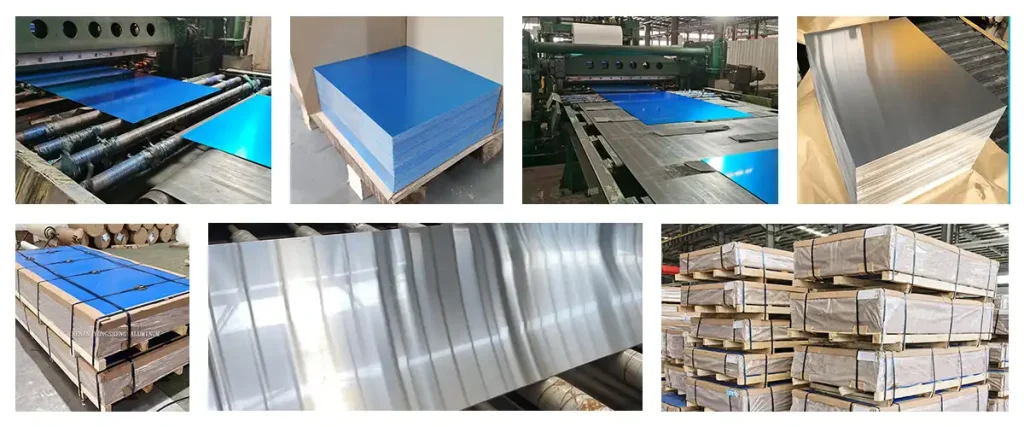

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes