The 6000 series aluminum alloy contains two elements, magnesium and silicon, and concentrates the advantages of the 4000 and 5000 series aluminum. This alloy has good process performance and is suitable for free forging, rolling, stamping and other process operations. It is widely used in the automobile industry, cell phones, computers and other 3C products, molds, precision processing machinery, shipbuilding, building facades, air-conditioning pipe manufacturing and other fields. Its typical representative grade 6061 aluminum plate, 6063 aluminum plate has medium strength, high plasticity and corrosion resistance, excellent weldability, good cold workability, is a widely used and promising alloy. This article will probably explain to you the 6000 series aluminum alloy manufacturing process, mechanical properties, common grades and main uses, to help you understand the series of aluminum plate.

6000 Series Aluminum Alloy Manufacturing Process

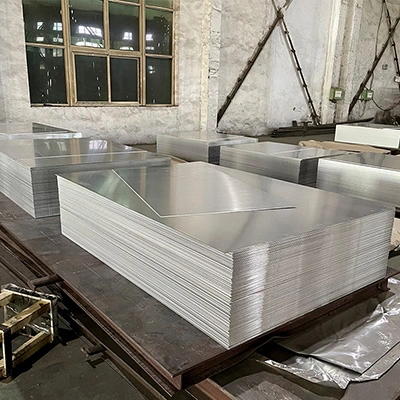

The manufacturing process of 6000 series aluminum alloy sheet generally includes casting, hot rolling, cold rolling and annealing.

Melting and casting: the aluminum alloy raw materials for the preparation of aluminum alloy plates are dosed according to the weight percentage, the prepared aluminum alloy raw materials are placed in the melting furnace and melted into liquid aluminum alloy, the melted aluminum alloy melt is poured into the refining furnace to refine, the refined aluminum alloy melt is melted and casted into aluminum alloy ingot by removing gas and impurities and online refinement, the aluminum alloy ingot is cut off the head and the tail of the casting ingot, and the surface of the casting ingot is milled to remove the shell layer, and then the casting ingot is heat-treated in a heating furnace for uniformization, the aluminum alloy ingot is first warmed up to 560℃ and held at 8~10h. Aluminum alloy ingot in the heating furnace for uniform heat treatment, the aluminum alloy ingot will first be heated to 560 ℃ insulation 8 ~ 10h;

Hot rolling:

The aluminum alloy ingot after homogenization heat treatment is first hot rough rolling, and then hot finish rolling to get 5.5mm aluminum alloy plate, the final rolling temperature is about 320 ℃ ± 10 ℃.

Cold rolling:

Once the desired thickness is achieved by hot rolling, the aluminum sheet is further processed by cold rolling. Cold rolling involves passing the hot rolled sheet through a series of cold rolling mills at room temperature, which in turn reduces the thickness of the sheet, refines the microstructure, and improves the surface finish and dimensional accuracy. Cold rolling also improves the strength and hardness of the aluminum sheet.

Annealing:

Cold rolled aluminum plates are annealed in order to eliminate internal stresses and improve their forming properties. The sheet is heated to a specific temperature and then slowly cooled in a controlled environment. Annealing helps soften the material, enhances its ductility, and improves its workability for subsequent processing steps such as forming and bending.

Subsequent processing:

After annealing, depending on the specific requirements of the intended application, aluminum plates may undergo additional finishing operations. These operations may include surface treatments such as cleaning, etching or coating to enhance the appearance of the sheet and protect it from corrosion. The sheet may also undergo cutting, slitting or shearing to obtain the desired size and shape.

6000 Series Aluminum Alloy Mechanical Properties

Typically, 6xxx aluminum sheet plate has a tensile strength in the range of 200 to 350 MPa (29,000 to 51,000 psi) and a yield strength typically in the range of 100 to 300 MPa (14,500 to 43,500 psi). The 6000 series aluminum alloy exhibits higher strength, which varies according to the alloy grade and state. It has a melting point in the range of approximately 580°C to 655°C (1076°F to 1211°F) and is easily cast and extruded. The presence of alloying elements such as magnesium and silicon provides a protective oxide layer on the surface that helps resist corrosion in a variety of environments, including outdoor exposure and marine conditions.

Aluminum 6000 series has a high thermal conductivity of about 150 to 200 W/m·K, and also exhibits excellent formability to create complex shapes through extrusion and bending processes. These two characteristics make the 6 series aluminum alloy is very used in the manufacture of electronic components (such as 6061 aluminum, 6063 aluminum for mobile phone card slots, mobile phone cases, etc.). 6000 series aluminum welding and plating performance is good. They can be successfully joined using a variety of welding techniques, including TIG (tungsten inert gas) welding and MIG (metal inert gas) welding.

6000 Series Aluminum Alloy Properties

The 6 series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloy elements and the Mg2Si phase as the strengthening phase. It is an aluminum alloy that can be strengthened by heat treatment. The alloy has the advantages of medium strength, high corrosion resistance, no stress corrosion cracking direction, good welding performance, unchanged corrosion performance in the welding zone, and good formability and process performance. When the alloy contains copper, the strength of the alloy can be close to that of the 2000 series aluminum alloy, and the process performance is better than that of the 2xxx series aluminum alloy, but the corrosion resistance becomes worse, and the alloy has good forging properties. The most widely used 6xxx series alloys are 6061 and 6063 alloys, which have the best comprehensive properties. Their main products are extruded profiles, which are the best extruded alloys. This alloy is widely used as construction profiles. Currently producing 6 series aluminum alloy grades: 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02, etc.

6000 Series Aluminum Corrosion Resistance

The 6000 series aluminum alloy forms a dense oxide layer on the surface to prevent further corrosion. The 6000 series aluminum alloy shows good corrosion resistance in a chloride environment. Compared with the 1000 series aluminum alloy, the 6000 series aluminum alloy contains more alloy elements and has more advantages in corrosion resistance. Compared with 7000 series aluminum alloys, 6000 series aluminum alloys may have slightly lower corrosion resistance in some specific environments, but still provide reliable performance.

6000 Series Aluminum Common Grades

| Alloy | Tensile Strength(MPa) | Melting Point(°C) | Heat Treating | Thickness(mm) | Elongation(%) | Yield Strength(Mpa) | Temper |

| 6005 | 215 | 585 | T5 tempering heat treatment | 0.10-350 | 12-16 | 170 | F,O,T4,T6,T651,H112 |

| 6061 | 275 | 595 | T6 tempering heat treatment | 0.10-350 | 12-17 | 240 | F,O,T4,T6,T651,H112 |

| 6063 | 185 | 655 | T5 tempering heat treatment | 0.10-350 | 8-12 | 145 | F,O,T4,T6,T651,H112 |

| 6082 | 310 | 555 | T6 tempering heat treatment | 0.10-350 | 10-13 | 290 | F,O,T4,T6,T651,H112 |

6005 Aluminum Alloy: It has good work ability and weld ability, and is commonly used in the manufacture of building materials, ships, rail vehicles, aerospace parts and components.

6061 Aluminum Alloy: a common high-strength aluminum alloy with good work ability and weld ability, commonly used in the manufacture of aerospace parts, automotive parts, bicycle parts, ships, building materials and so on.

6063 Aluminum Alloy: It has good work ability and weld ability, and is commonly used in the manufacture of building materials, industrial profiles, automotive parts, etc.

6082 Aluminum Alloy: With good strength and corrosion resistance, it is commonly used in the manufacture of aerospace parts, automotive parts, bicycle parts, and construction materials.

Applications For 6000 Series Aluminum Alloys

Automotive

The 6000 series alloys are heat-treated, strengthenable aluminum alloys that are suitable for use as lightweight materials for automotive applications. Such as automobile body, automobile chassis, wheels, fuel tanks, aluminum cans, machine covers, motor housings and other structures. Such as the recent emergence of 6061 aluminum alloy carcass is a good example, 6005 aluminum is commonly used in the manufacture of fuel tanks, pipelines and so on.

Electrical and Electronic

The electrical and electronics industry benefits from the excellent thermal and electrical conductivity of the 6000 series aluminum alloys. They are used in computer housings, cell phone housings, mobile phone card slots, camera lenses, radiators, heat exchangers, high pressure vessels, LED lighting fixtures, electric fences and conductor strips.

Consumer Industries

6000 series aluminum alloys are used in a variety of consumer applications, including industrial molds (6063 and 6082 aluminum are commonly used), furniture, sports equipment, bicycles and kitchen appliances. These alloys provide a balance of strength, appearance and corrosion resistance, making them suitable for a wide variety of consumer products.

5000 Vs 6000 Series Aluminum

6000 series aluminum alloy has strong corrosion resistance in general atmospheric settings, particularly chloride corrosion. The 5000 series aluminum alloy is well-known for its high corrosion resistance in oxidizing situations such as seawater, making it ideal for maritime applications. In terms of strength, the 6000 series aluminum alloy may achieve increased strength and hardness by adding alloy components such as silicon and magnesium, and it is appropriate for applications needing high strength and lightweight. 5 series aluminum alloys are known for their excellent plasticity and weldability, and perform well in applications requiring good formability. In terms of practical applications, 6 series aluminum alloys are commonly used in aerospace, transportation, construction and automotive industries, and are suitable for applications requiring high strength and good corrosion resistance. The 5xxx series aluminum alloy is mainly used in fields such as marine industry, chemical equipment and maritime construction that need to resist seawater erosion.

6000 Vs 7000 Series Aluminum

In terms of strength, 7000 series aluminum alloy has higher strength than 6000 series aluminum alloy. Due to the addition of alloying elements such as zinc and copper, the 7xxx series aluminum alloys excel in applications requiring higher strength. 6000 series aluminum alloys may have lower strength at elevated temperatures. The corrosion resistance of the two is also different: the 6000 series has better resistance to chloride corrosion in general atmospheric environments; the 7000 series aluminum alloy has good corrosion resistance, especially in corrosion resistance, stress corrosion resistance and fatigue resistance. It exhibits excellent characteristics in terms of crack propagation and other aspects.

Based on their different characteristics, 6000 series aluminum alloys and 7000 series aluminum alloys have different application fields. 6000 series aluminum alloys are widely used in aerospace, transportation, construction and automotive industries, and are suitable for projects that require higher strength and better corrosion resistance. 7000 series aluminum alloys are commonly used in aerospace, defense and sports equipment fields, such as aircraft structural components, missile casings and bicycle frames, where extremely high strength and corrosion resistance are required.