Aluminum Sheet for Bus Roof

Aluminum Alloy: 3003, 5052 etc

Temper: O, H14, H16, H18 etc

Thickness: 0.5mm-10mm, usually 1.0mm, 1.2mm, 1.5mm, 2.0mm, etc.

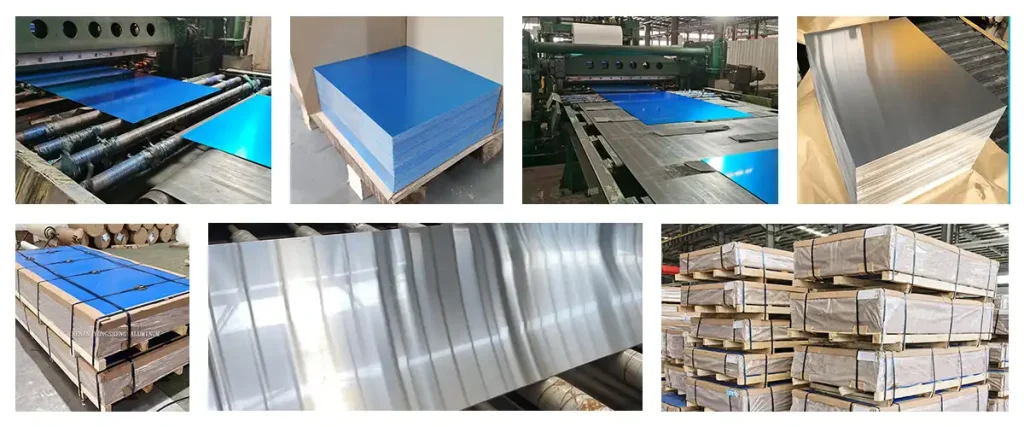

Delivery: Ready stock: 7-10 days, future goods: 15-30 days

Width: 1000mm-2000mm, usually 1000mm, 1200mm, etc.

Typical Application: Bus roof, GIS shell aluminum plate, automobile engine outer plate, automobile fuel tank aluminum plate, etc.

What is a Bus Roof?

Aluminum sheets are also used in bus roofs. The bus roof refers to the top part covering the bus body, usually made of aluminum alloy, steel or plastic. Generally speaking, the bus roof needs to have sufficient strength and rigidity to withstand the wind pressure and vibration when the vehicle is driving, and it also needs to have a certain degree of flexibility to adapt to the deformation and twisting of the vehicle body. Aluminum sheet is one of the commonly used materials for passenger car roofs because it has the advantages of light weight, high strength, corrosion resistance, and easy processing. The surface treatment of bus roofs requires appropriate methods to ensure the appearance and performance of the product. Commonly used surface treatment methods include anodizing, spraying, electrophoretic coating, etc.

Advantages of Bus Roof Aluminum Sheet

1. Greatly reduce the weight of the car body to reduce energy consumption, reduce environmental pollution, and improve the fuel economy performance of the bus.

2. Reducing the weight of the vehicle body can move the vehicle’s center of gravity downwards, making the vehicle run more smoothly and further improve product safety performance.

3. The aluminum alloy car body has strong corrosion resistance, the product is durable, and the product quality is more guaranteed.

Why Choose 3003 Aluminum Sheet for Bus Roof?

1. Good corrosion resistance: 3003 aluminum plate has good corrosion resistance, can be used for a long time in harsh environments, and is not easy to rust and corrode, thereby ensuring the service life of the bus roof.

2. High strength: 3003 aluminum plate has high strength and can withstand the weight of the bus roof and external impact force, thereby ensuring the stability and safety of the bus roof.

3. Good formability: 3003 aluminum plate has good formability and can be easily processed into passenger car roofs of various shapes and sizes to meet the different needs of customers.

4. Easy to weld: 3003 aluminum plate is easy to weld and can be well connected with other materials, thus ensuring the integrity and stability of the bus roof.

Why Choose 5052 Aluminum Sheet for Bus Roof?

1. 5052 stretched aluminum plate is an aluminum-magnesium alloy aluminum plate. This alloy has high strength, especially fatigue resistance, and high plasticity and corrosion resistance.

2. 5052 stretched aluminum plate also contains a small amount of chromium. The role of chromium is similar to that of manganese. It improves the resistance to stress corrosion cracking, increases the strength of the base metal and welds, and reduces the tendency of welding cracks.

Application Display:

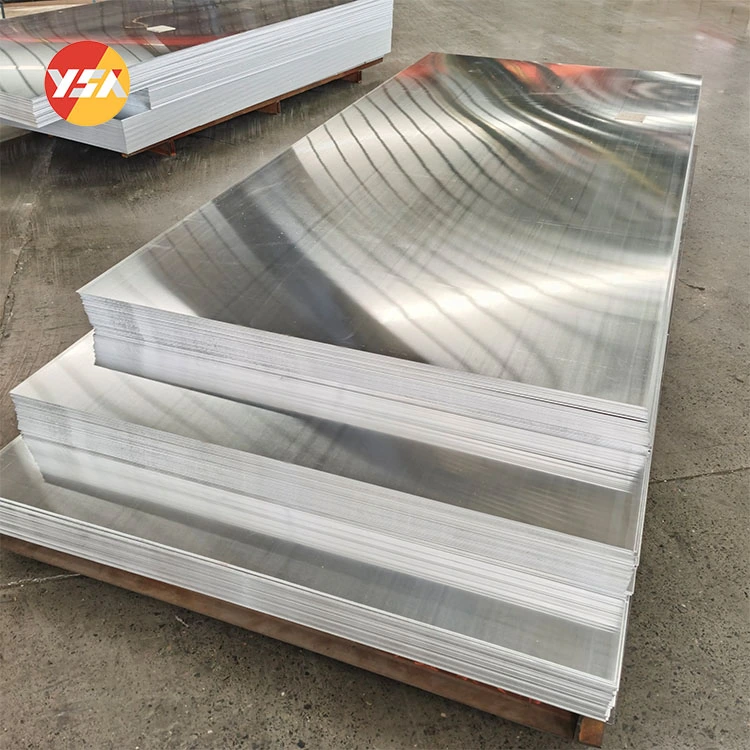

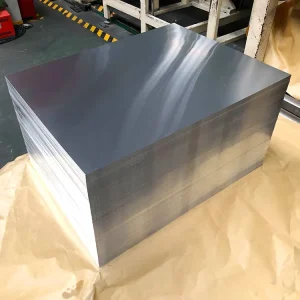

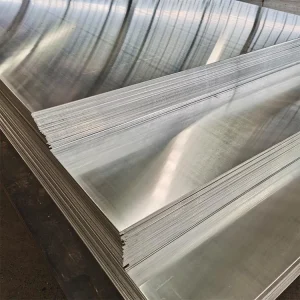

Product & Packaging Photos

Why Choose Us

Yongsheng Aluminum is a leading aluminum products manufacturer&supplier in China with 25 years of export experience. Our outstanding product quality, price, and always on-time delivery has won us many long term partners and gained a great reputation worldwide. We provide one-stop product solution for both CC&DC aluminum products.

Business Handling Processes